What is a Push Back Racking System?

- 20/12/2024

- Posted by: macgad-admin

- Category: Racking System

What is a Push Back Racking System?

For many Malaysian warehouses looking to save space and streamline inventory access, push back racking offers an efficient solution. This innovative storage system utilizes inclined rails and trolleys to store multiple pallets in a single lane, thereby maximizing available space without expanding the floor area. In this article, we’ll explore how it works, why it’s beneficial, and what you should consider for installation.

How Does a Push Back Racking System Work?

Push back racking relies on rails and wheeled trolleys to store pallets in deep lanes. Each time a new pallet is loaded, it pushes the others back. This simple yet effective mechanism enables efficient Last-In, First-Out (LIFO) access, which, importantly, requires no manual rearranging.

For instance, in a three-deep push back rack, loading the first pallet places it at the front. Furthermore, adding a second pallet then pushes the first one back, and so on. Consequently, when the front pallet is retrieved, the next pallet automatically rolls forward. This allows workers to quickly access the following load without additional effort.

Benefits of Push Back Racking System

Push back racking offers significant advantages, making it a popular choice in high-density storage environments. Here are some of its key benefits:

- Increased Storage Density: Storing multiple pallets in a single lane helps optimize floor space. As a result, this system can increase storage capacity by up to 35%.

- Efficient Use of Space: Additionally, because push back racks reduces aisle needs, it frees up valuable space in the warehouse, which is a critical factor for facilities with limited floor area.

- Faster Picking Times: By allowing pallets to roll forward as they’re retrieved, this system streamlines picking times. This efficiency is particularly important in high-rotation warehouses.

- Flexibility for Different Pallet Types: In addition, push back racking accommodates various pallet sizes and weights, making it suitable for diverse industries ranging from food distribution to retail.

When to Use a Push Back Racking System

So, when should a warehouse consider push back racks? Here are a few situations where this storage system shines:

- High-Density Storage: If warehouses need dense storage, they can use push back racks to store multiple pallets per lane, thereby maximizing available capacity.

- Limited Floor Space: Facilities facing high rental costs can install push back racking to avoid expanding storage space.

- LIFO Inventory Management: Moreover, this system is ideal for Last-In, First-Out inventory, where newer stock should be readily accessible.

Push Back Racking System vs. Other Racking Systems

To determine whether push back racking is the best option, let’s compare it with other systems:

| Feature | Push Back Racking | Selective Racking | Drive-In Racking | Double Deep Racking |

|---|---|---|---|---|

| Storage Density | High | Medium | Very High | High |

| Accessibility | Moderate | High | Low | Moderate |

| Best For | LIFO inventory | Variety of SKUs | Bulk storage | High-volume storage |

For example, selective racking provides quick access to each SKU but requires more aisle space, which subsequently lowers its storage density. In contrast, push back racking balances storage density with moderate accessibility, making it an ideal choice for frequently rotated items.

Installation Guide for a Push Back Racking System in 2024

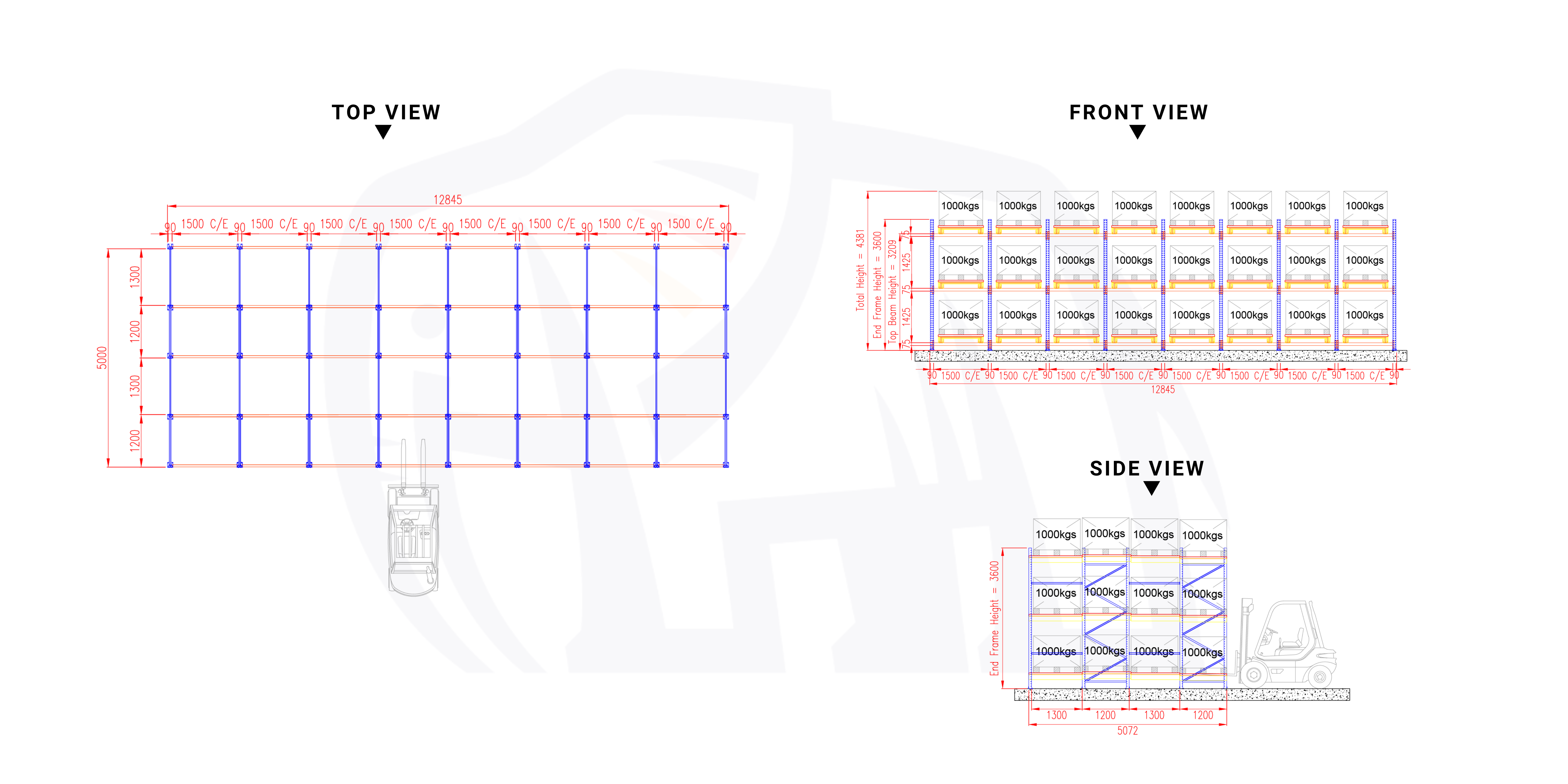

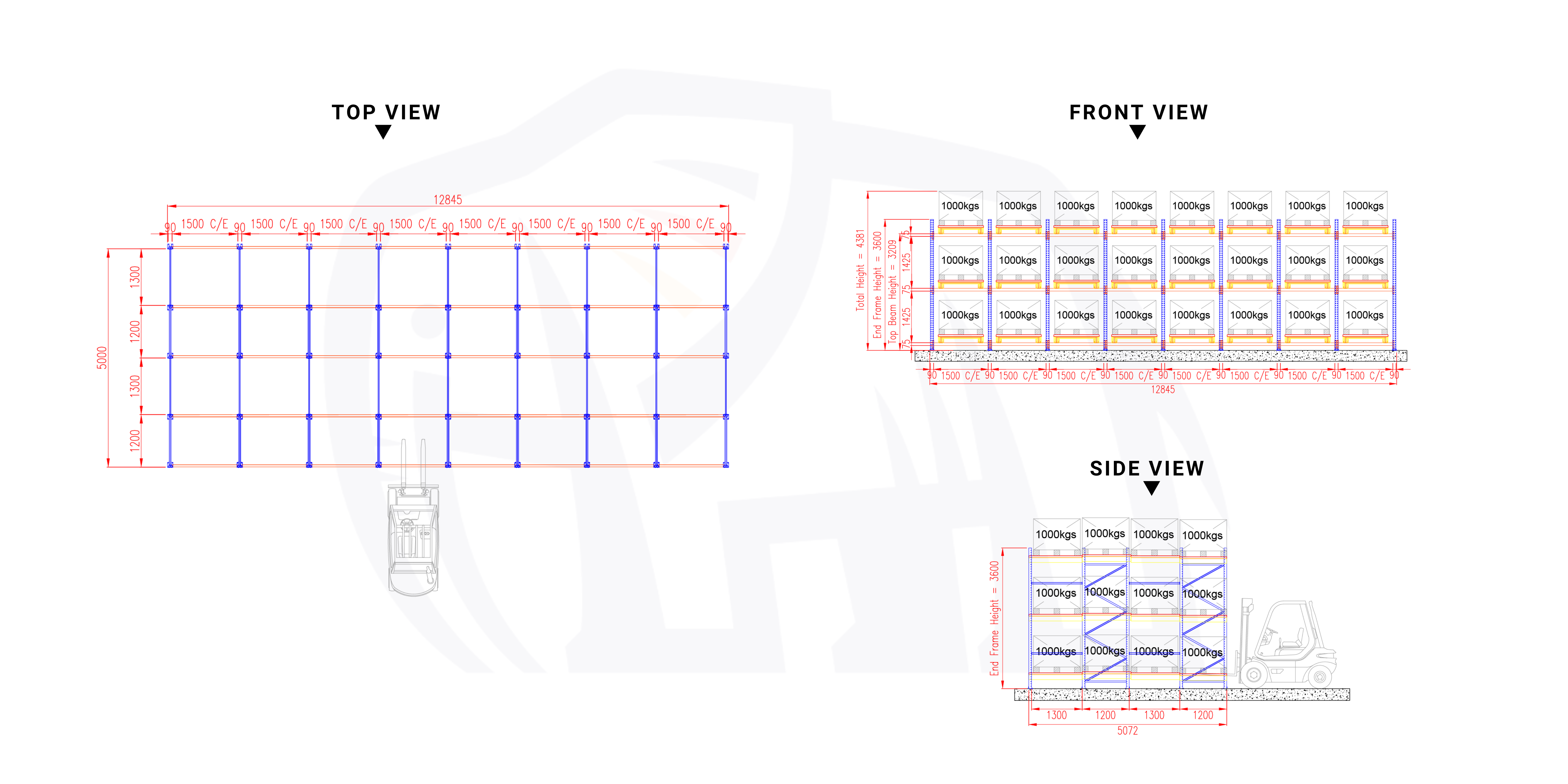

Setting up push back racking can be straightforward, but careful planning makes the process smoother. Here’s a quick guide to help you get started:

- Plan Your Layout: First, begin by measuring your warehouse space and considering configurations. Importantly, this racking system allow for denser storage with fewer aisles, creating more space overall.

- Check Load Capacity: Ensure racks can support pallet weights. Generally, standard push back racks handle loads between 500 and 2,000 kilograms per level.

- Secure Frames and Rails: Properly anchor frames and install rails to allow pallets to roll smoothly on the incline.

- Set Aisle Widths: Lastly, maintain aisle widths that fit your forklifts based on their type and turning radius.

Cost of Installing a Push Back Racking System

In Malaysia, push back racking systems generally start at around RM500 per pallet position. However, prices can vary based on the provider and customization options. Therefore, it’s best to contact suppliers for an accurate estimate that reflects your specific requirements.

Choosing the Right Provider

Selecting the right provider for your racking system is essential for ensuring quality and support. Here are some tips for finding a reliable supplier:

- Research Local Experts: Begin by choosing a Malaysian company with experience in the local market; their familiarity with warehousing needs in the area can be invaluable.

- Check Certifications: Ensure that the provider meets local and international quality standards for durability and safety.

- Look for Comprehensive Support: Additionally, seek out providers that offer end-to-end support, including consultation, installation, and after-sales service.

- Compare Prices and Warranties: Finally, get quotes from multiple suppliers and review warranty terms to make the best long-term investment.

Ready to enhance your warehouse efficiency? At HYPERACK, we specialize in double deep racking systems tailored to meet your specific needs. Contact us today for a FREE consultation, and let our experts help you optimize your storage solution! Explore our social media to see real-life projects in action.

Conclusion

In conclusion, push back racking provides a practical and high-density storage solution for Malaysian warehouses. By storing multiple pallets per lane and reducing aisle space, this system significantly increases storage efficiency. Moreover, push back racking not only saves space but also improves inventory management, making it an ideal choice for warehouses with limited floor area and high-volume needs.

How Hyperack Plan Your Racking System?

- Expertise: We dive deep into your warehouse space to determine the best racking configurations tailored to your needs.

- High-Tech Solutions: Our AutoCAD designs maximize storage while ensuring your team has ergonomic access to what they need.

- Side-by-Side Comparisons: Our planning process allows you to compare layout options easily, helping you make informed decisions.

- Data-Driven ROI Calculation: We provide detailed numerical data for each layout, empowering you to understand the impact on your bottom line.

- Customization: Our custom racking systems are built to meet any unique requirements, ensuring the best approach for any facility.