What is a Very Narrow Aisle Racking System?

- 06/12/2024

- Posted by: macgad-admin

- Category: Racking System

What is a VNA Very Narrow Aisle Racking System?

In the competitive world of warehouse management, space optimization is a top priority for many Malaysian businesses. The VNA, or Very Narrow Aisle racking system, is designed specifically for facilities looking to make the most out of limited floor space. This innovative system allows warehouses to pack racking closer together while still maintaining efficient access to goods. Using specialized forklifts to maneuver through aisles as narrow as 1.6 meters, VNA racking enables companies to maximize both vertical and horizontal spaces.

How Does a VNA Very Narrow Aisle Racking System Work?

At the heart of VNA racking is its incredibly slim aisle design. Unlike traditional racking, VNA systems place racks closer together, leaving very narrow aisles in between. Specialized forklifts, often equipped with wire or rail guidance, can safely navigate these aisles and reach items stored at various heights. As a result, the VNA racking system ensures maximum storage density without requiring more warehouse space. This is especially beneficial for businesses in high-rent areas where every square meter counts.

By making use of narrow aisle space and high shelving, VNA racking systems provide an efficient storage solution. This setup is particularly valuable for warehouses that manage a large inventory volume, where every inch of space can significantly impact productivity.

Benefits of a VNA Very Narrow Aisle Racking System

- Maximizes Storage Capacity

Firstly, VNA racking systems increase storage density by minimizing aisle width. By reducing wasted space, VNA racking can store more products in the same area, helping warehouses in Malaysia meet high storage demands without needing additional floor space. - Streamlines Inventory Access

Despite the narrower aisle design, VNA systems still allow for quick and efficient access to all inventory items. The specialized forklifts used can maneuver smoothly in the tight aisles, which keeps picking and stocking times low and operations flowing. - Improves Warehouse Layout

Another advantage of VNA very narrow aisle racking is that it creates an organized and structured warehouse layout. The slim aisles and vertical storage improve workflow, making it easier to manage inventory, locate items, and keep warehouse operations running smoothly. - Cost-Efficient Over Time

Although the initial costs of VNA systems might be higher due to the specialized equipment needed, the system often pays for itself over time. Increased storage capacity and efficient layouts lead to long-term savings, especially for warehouses with high inventory turnover.

When to Use a VNA Very Narrow Aisle Racking System

For certain needs, a VNA racking system can be a game changer. Here are a few scenarios where it may be especially effective:

- High-Volume Inventory: VNA systems are ideal for warehouses needing to store a large quantity of goods in limited space. The high-density setup makes it possible to accommodate more inventory without needing to expand.

- Frequent Stocking and Picking: If your warehouse requires regular stocking and picking, VNA racking provides the necessary efficiency while saving space.

- Existing Specialized Equipment: Warehouses with, or planning to invest in, specialized VNA forklifts will benefit most from this system since it requires VNA-compatible equipment for optimal performance.

VNA Racking System vs. Other Racking Systems

To determine if VNA racking is the best choice for your needs, it’s helpful to compare it with other racking systems:

| Feature | VNA Racking | Selective Racking | Drive-In Racking | Push Back Racking |

|---|---|---|---|---|

| Storage Density | Very High | Medium | High | High |

| Accessibility | High | High | Low | Moderate |

| Equipment Needed | VNA Forklifts | Standard Forklifts | Specialized Forklifts | Specialized Forklifts |

| Best For | High-density storage | Variety of items | Bulk storage | FIFO inventory |

For instance, selective racking offers easy access to each pallet, while drive-in racking focuses on maximizing storage density but limits access to last-in items. VNA racking provides a balance, allowing both high storage density and easy accessibility, making it ideal for high-demand environments.

Installation Guide for a VNA Racking System in 2024

Here’s a quick guide for installing a VNA system to help ensure you make the most of your warehouse space:

- Evaluate Layout Needs: First, measure your floor space to calculate the best layout for maximizing storage capacity.

- Check Load Capacity: Ensure the racks are strong enough to hold your inventory. VNA racking can typically handle heavy loads at various heights.

- Install Safety Guides: Next, add wire or rail guidance to keep forklifts safely aligned in narrow aisles.

- Choose Compatible Equipment: Make sure you have VNA-compatible forklifts, as these are essential for accessing items in tight spaces.

Cost of Installing a VNA Racking System

The cost of a VNA very narrow aisle racking system depends on several factors, including your warehouse’s specific requirements. Basic VNA installations in Malaysia start at around RM500 per pallet position, but this can vary with custom designs and additional features. For accurate pricing, consulting multiple suppliers is recommended. The initial cost may be higher than some systems, but the long-term benefits often make it a cost-effective investment.

Choosing a Reliable Provider

A reputable provider is essential for a successful VNA racking installation. Here are a few key considerations:

- Industry Experience: Choose providers familiar with the Malaysian market and well-experienced with VNA systems.

- Compliance and Certifications: Ensure that the provider follows safety standards and regulations.

- Customer Support: Reliable providers offer installation support, maintenance, and customer service.

- Pricing and Warranty Options: Finally, compare quotes and warranties from multiple providers to make an informed choice.

Ready to enhance your warehouse efficiency? At HYPERACK, we specialize in double deep racking systems tailored to meet your specific needs. Contact us today for a FREE consultation, and let our experts help you optimize your storage solution! Explore our social media to see real-life projects in action.

Conclusion

In summary, a VNA very narrow aisle racking system offers an effective solution for Malaysian businesses aiming to optimize warehouse space. With high-density storage and efficient access, this system can help streamline operations and reduce long-term costs. Whether for a large or small inventory, VNA racking provides a balanced solution that enhances both accessibility and storage capacity.

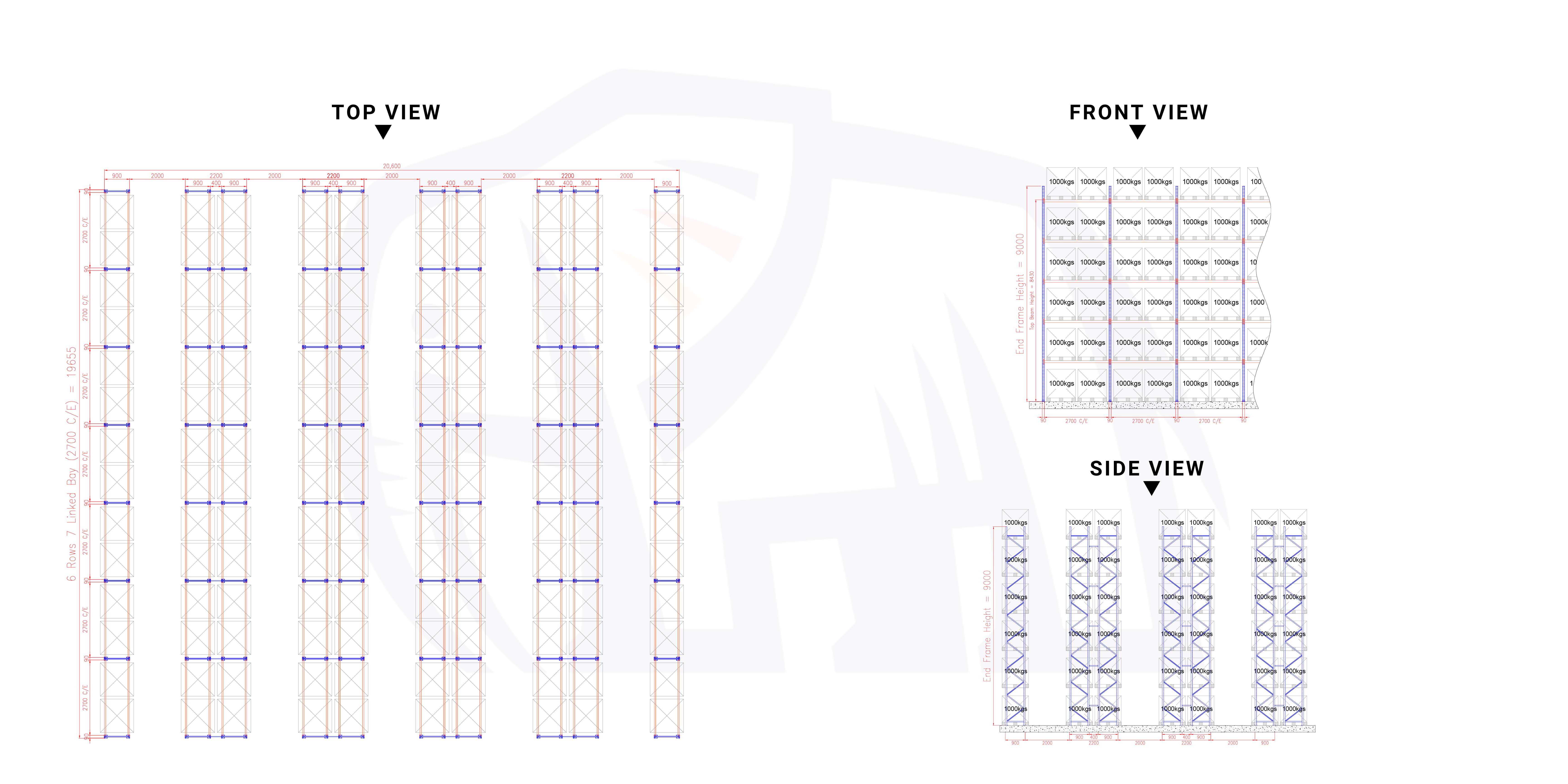

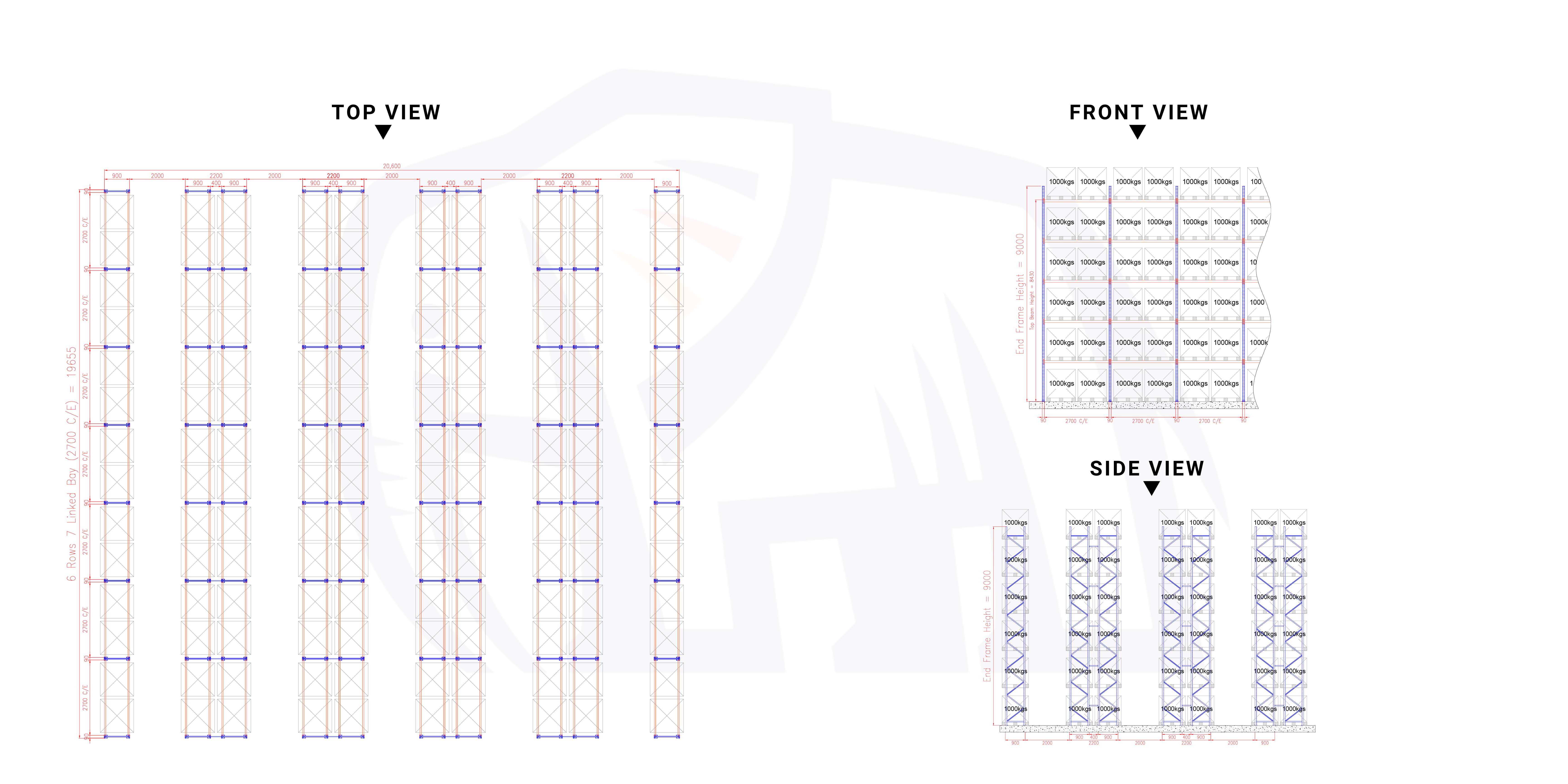

How Hyperack Plan Your Racking System?

- Expertise: We dive deep into your warehouse space to determine the best racking configurations tailored to your needs.

- High-Tech Solutions: Our AutoCAD designs maximize storage while ensuring your team has ergonomic access to what they need.

- Side-by-Side Comparisons: Our planning process allows you to compare layout options easily, helping you make informed decisions.

- Data-Driven ROI Calculation: We provide detailed numerical data for each layout, empowering you to understand the impact on your bottom line.

- Customization: Our custom racking systems are built to meet any unique requirements, ensuring the best approach for any facility.