Warehouse racking

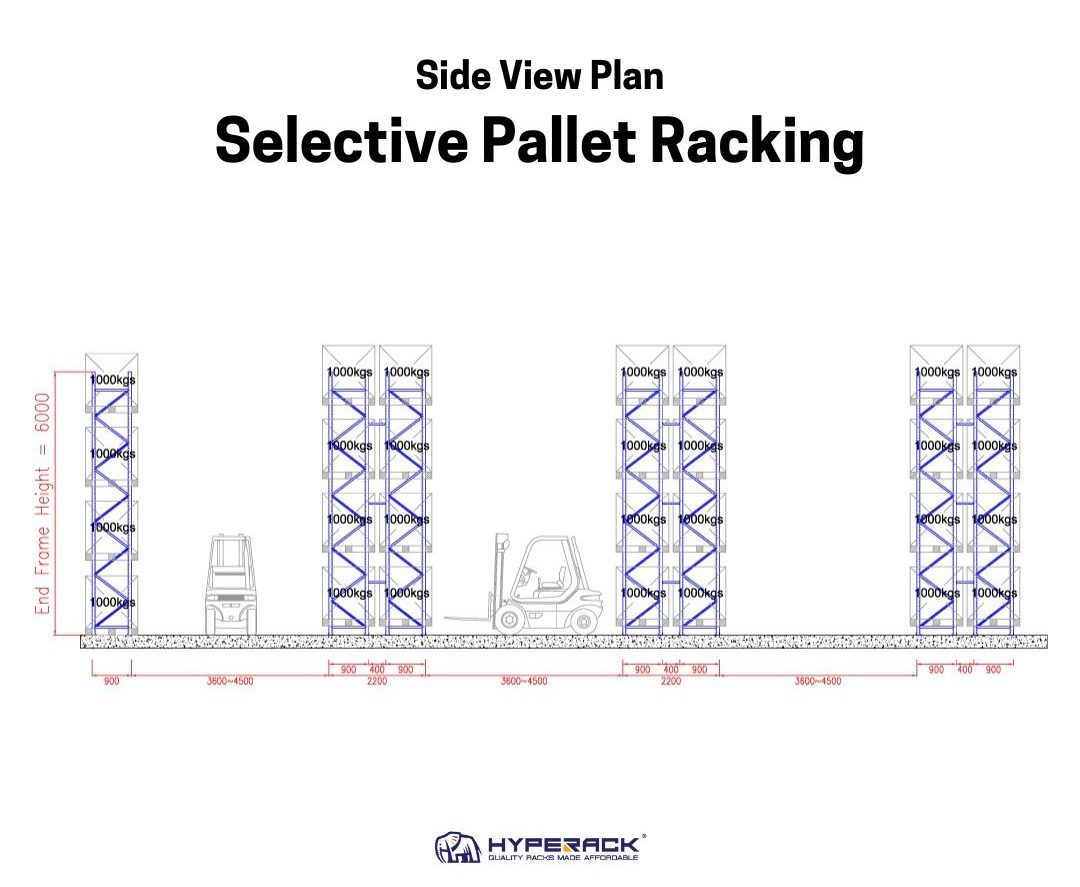

Selective Pallet Racking System

When it comes to warehouse storage solutions, selective racking stands out as the most common and versatile choice. Selective racking systems are designed to offer direct access to each pallet stored on the racks, eliminating the need to move other pallets to reach a specific item. This feature makes selective racking exceptionally efficient for operations that handle a large number of SKUs and require frequent order picking.

At Hyperack, our selective pallet racking system is renowned for its efficiency and practicality. As the most popular form of pallet racking available, selective racking offers a significant advantage in terms of accessibility and flexibility. This system ensures 100% selectivity, allowing you to retrieve any pallet without disturbing others, which is crucial for managing diverse inventories and optimizing space utilization.

Ideal for

- Fast Moving Consumer Goods (FMCG)

- Inventory is rapidly depleted and restocked (called quick turnover)

- Different categories of Goods

Advantages

- Lowering Structure Costs

- Low floor area utilization

- Good stock rotation

- Good order picking; 100% selectivity

- Rapid handling of all types of palletized goods

- Can be used in conjunction with all types of lift trucks

5 Easy Steps

1. Enquiry

Your journey begins with a simple enquiry. Once we receive your request, our team will review the details and match you with the right expert. We’ll then arrange a quick call or email to learn more about your goals and expectations.

2. Free Consultation

After your initial consultation, we’ll arrange a site visit to assess your space and needs in detail. You’ll meet your dedicated project manager, who will guide the process from start to finish—ensuring everything runs smoothly and efficiently.

3. 3D CAD Design

After the site survey, your project manager will recommend layout options tailored to your space and needs. We’ll then create accurate 3D CAD designs to help you visualise exactly how your facility will look once complete.

4. Instant Quote

You’ll receive a free, personalised quote with a full breakdown of the recommended equipment. We offer high-quality products at competitive prices, with reliable delivery times to keep your project on schedule.

5. Installation

We’ll agree on an installation schedule that suits your operations. Our accredited team will complete the setup, conduct a final inspection with you, and provide follow-up support, including annual safety checks.

Ready to make a change?

We are here to help you choose the best racking for your business. Schedule a call with our representative today.

FAQ

What are the safety considerations when installing a Selective Pallet Racking System?

Ensuring safety involves proper installation, regular inspections, and adherence to weight capacities. It’s crucial to train staff on correct loading techniques and to use safety accessories like column protectors and guard rails to prevent accidents.

How does Selective Pallet Racking compare to other racking systems in terms of cost and efficiency?

Selective Pallet Racking is generally more cost-effective and offers 100% accessibility to each pallet, making it suitable for warehouses with a wide variety of products. However, for higher storage density, systems like drive-in or push-back racking might be more efficient.

What types of forklifts are compatible with Selective Pallet Racking Systems?

Standard counterbalance forklifts and reach trucks are commonly used with Selective Pallet Racking. The aisle width should be planned to accommodate the specific type of forklift in use.

Can Selective Pallet Racking be customized for different pallet sizes and weights?

Yes, Selective Pallet Racking System are highly customizable and can be adjusted to accommodate various pallet sizes and weights, ensuring optimal storage solutions for diverse inventory requirements.

What maintenance practices are recommended for Selective Pallet Racking System?

Regular maintenance includes inspecting for damage, ensuring load capacities are not exceeded, tightening any loose bolts, and replacing any compromised components to maintain structural integrity and safety.

Can Selective Racking Systems be used for mixed product storage (various SKUs)

Yes, Selective Racking Systems are highly versatile and ideal for storing mixed SKUs. Each pallet can be accessed individually without moving others, making it suitable for warehouses with a wide range of products or varying inventory turnover rates. This flexibility helps in managing inventory efficiently, regardless of SKU diversity.

Are there specific safety training requirements for employees working with Selective Racking Systems?

Yes, employees should receive safety training specific to handling and operating around Selective Racking Systems. This includes:

- Proper forklift operation to avoid collisions with the racking system.

- Awareness of weight limits for each rack to prevent overloading.

- Procedures for safely loading and unloading pallets.

- Identifying signs of racking damage or instability to report for maintenance.

Regular safety drills and inspections are also recommended to ensure compliance with workplace safety standards.

What are the common challenges faced when using a Selective Racking System, and how can they be resolved?

Common challenges include:

- Overloading racks: Exceeding the load capacity can lead to structural failure.

Solution: Conduct load assessments and clearly label weight limits on racks. - Forklift collisions: Accidental impacts can damage racking systems.

Solution: Install protective guards and train operators on proper navigation. - Space utilization: Suboptimal racking layouts may waste storage capacity.

Solution: Consult a professional for custom designs tailored to your space and needs. - Damage from improper pallet placement: Pallets not placed correctly may fall or damage beams.

Solution: Ensure staff is trained on correct placement techniques.

How do you determine the right height and width for a Selective Racking System?

Usually, a racking provider like Hyperack will provide you with a calculation and a blueprint draft for the layout, based on these factors. However, it’s important to check and verify these calculations to ensure they meet your warehouse’s specific requirements. You can do this by:

- Pallet dimensions: The size and type of pallets being used dictate the rack’s beam length and spacing.

- Ceiling height: The maximum rack height depends on the warehouse’s ceiling clearance and sprinkler system regulations.

- Forklift reach: Ensure the rack height is within the lifting capacity of your forklifts.

- Aisle width: Aisles must accommodate the type of forklift or equipment used for pallet retrieval.

- Load capacity: Racks must support the total weight of stored goods without compromising safety.

Consulting a racking specialist is always recommended to ensure the layout meets both operational efficiency and safety standards.

Can Selective Racking Systems be expanded or relocated in the future?

Yes, Selective Racking Systems are modular and can be easily expanded or relocated. Additional racks can be integrated into the existing system to increase storage capacity. If relocation is required, the racking system can be dismantled, transported, and reassembled at a new location. It is recommended to hire professional installers for these processes to ensure safety and compliance with structural standards.