What is a Gravity Flow Racking System?

- 17/12/2024

- Posted by: macgad-admin

- Category: Uncategorized

What is a Gravity Flow Racking System?

In today’s competitive logistics landscape, businesses are continually seeking effective storage solutions. One option that has been gaining traction is the gravity flow racking system. This innovative storage solution enables products to move effortlessly along inclined tracks, utilizing gravity to enhance efficiency. As a result, companies can streamline their inventory management processes. In this article, we will explore the concept of gravity flow racking systems, how they operate, and why they might be the right fit for your warehouse.

How Gravity Flow Racking Systems Work?

At the heart of gravity flow racking systems lies a simple yet effective mechanism. Specifically, these racks feature inclined tracks or rollers that facilitate the movement of pallets or cartons. When workers load products onto the rack, the items roll down toward the picking area, driven by gravity. Consequently, the system inherently supports a “first-in, first-out” (FIFO) inventory method, ensuring that older stock gets picked first.

Moreover, this arrangement proves particularly advantageous for businesses managing perishable items. It helps minimize spoilage and maintain product quality. Additionally, by maximizing vertical space and providing easy access to inventory, these systems significantly enhance warehouse efficiency.

Benefits of Gravity Flow Racking Systems

- Simplified Inventory Management

One standout feature of gravity flow systems is their ability to simplify how businesses manage inventory. By implementing the FIFO approach, companies can reduce waste and ensure older items sell first. As a result, this efficiency is crucial for industries like food and beverage, where maintaining freshness is essential. - Boosted Picking Efficiency

Another important advantage lies in increased picking efficiency. With products flowing directly to the picking area, employees can retrieve items quickly. Thus, this improvement leads to faster order fulfillment, enhancing customer satisfaction. - Maximized Space Utilization

Gravity flow systems excel at optimizing vertical storage space. They allow businesses to fully utilize warehouse height, which means more items can be stored without needing additional floor space. Therefore, this capability proves especially beneficial for operations located in urban areas, where space can be costly. - Cost Savings on Labor

Finally, these systems contribute to lower labor costs. With a well-designed layout and easy access to products, employees spend less time searching for items. Consequently, this operational efficiency helps reduce overall costs, positively impacting the company’s bottom line.

When to Use Gravity Flow Racking Systems?

Gravity flow racking systems shine in specific contexts. For instance, here are a few scenarios where this system proves advantageous:

- High Turnover Products: If your business deals with fast-moving inventory, the FIFO method ensures effective product rotation.

- Time-Sensitive Items: Companies managing perishable goods benefit significantly from the efficiency of these systems, as they help reduce waste.

- Urban Warehouses: For businesses operating in tight spaces, utilizing vertical storage capacity enhances overall efficiency.

Gravity Flow Racking vs. Other Storage Solutions

To better understand whether a gravity flow racking system suits your needs, consider how it compares to other storage options:

| Feature | Gravity Flow Racking | Selective Racking | Drive-In Racking | Push Back Racking |

|---|---|---|---|---|

| Storage Density | High | Medium | High | High |

| Accessibility | High | High | Low | Moderate |

| Equipment Requirements | Standard Forklifts | Standard Forklifts | Specialized Forklifts | Specialized Forklifts |

| Best Suited For | FIFO inventory | Variety of SKUs | Bulk storage | FIFO inventory |

For example, while selective racking provides quick access to pallets, it may not utilize space as efficiently as gravity flow systems do. In contrast, drive-in racking maximizes storage but complicates inventory rotation. Ultimately, gravity flow systems strike a balance, offering both accessibility and efficient space use.

Installation Guide for a Gravity Flow Racking System in 2024

Setting up a gravity flow racking system involves careful planning. Here’s a simple guide to help you through the process:

- Evaluate Your Warehouse Layout: Start by assessing your warehouse space and determining the most effective configuration for your racking system.

- Choose the Right Equipment: Select gravity flow rails and supports that match the weight and size of your products.

- Ensure Proper Incline: It’s crucial to set the correct incline for the gravity flow system to function properly, typically between 3 to 5 degrees.

- Conduct Comprehensive Testing: After installation, test the system thoroughly to confirm that items move smoothly and make any necessary adjustments.

Cost of Installing a Gravity Flow Racking Systems

The cost of installing a gravity flow racking system can vary based on specific requirements. Typically, basic installations start around RM600 per pallet position, influenced by factors like materials and design choices. To get the best value, contact several suppliers for quotes. Investing in this system can yield long-term savings through enhanced efficiency and reduced waste.

Best Racking System Provider?

Selecting the right provider is critical for successful installation. Here are some helpful tips:

- Look for Experience: Choose companies with a solid reputation in gravity flow systems, especially those familiar with the Malaysian market.

- Verify Quality Standards: Ensure the provider adheres to industry standards and safety regulations, which guarantees product quality.

- Assess Customer Support: Opt for a provider that offers excellent customer service, including installation help and ongoing support.

- Compare Quotes and Warranty Terms: Evaluate quotes from multiple suppliers and check warranty options to ensure the best value for your investment.

Ready to enhance your warehouse efficiency? At HYPERACK, we specialize in double deep racking systems tailored to meet your specific needs. Contact us today for a FREE consultation, and let our experts help you optimize your storage solution! Explore our social media to see real-life projects in action.

Conclusion

In conclusion, gravity flow racking systems present a practical and efficient solution for optimizing warehouse storage. By maximizing space, ensuring proper inventory rotation, and improving picking efficiency, these systems can be a valuable asset for businesses. If you’re seeking to enhance your warehouse operations, a gravity flow racking system may provide the effective answer you need.

How Hyperack Plan Your Racking System?

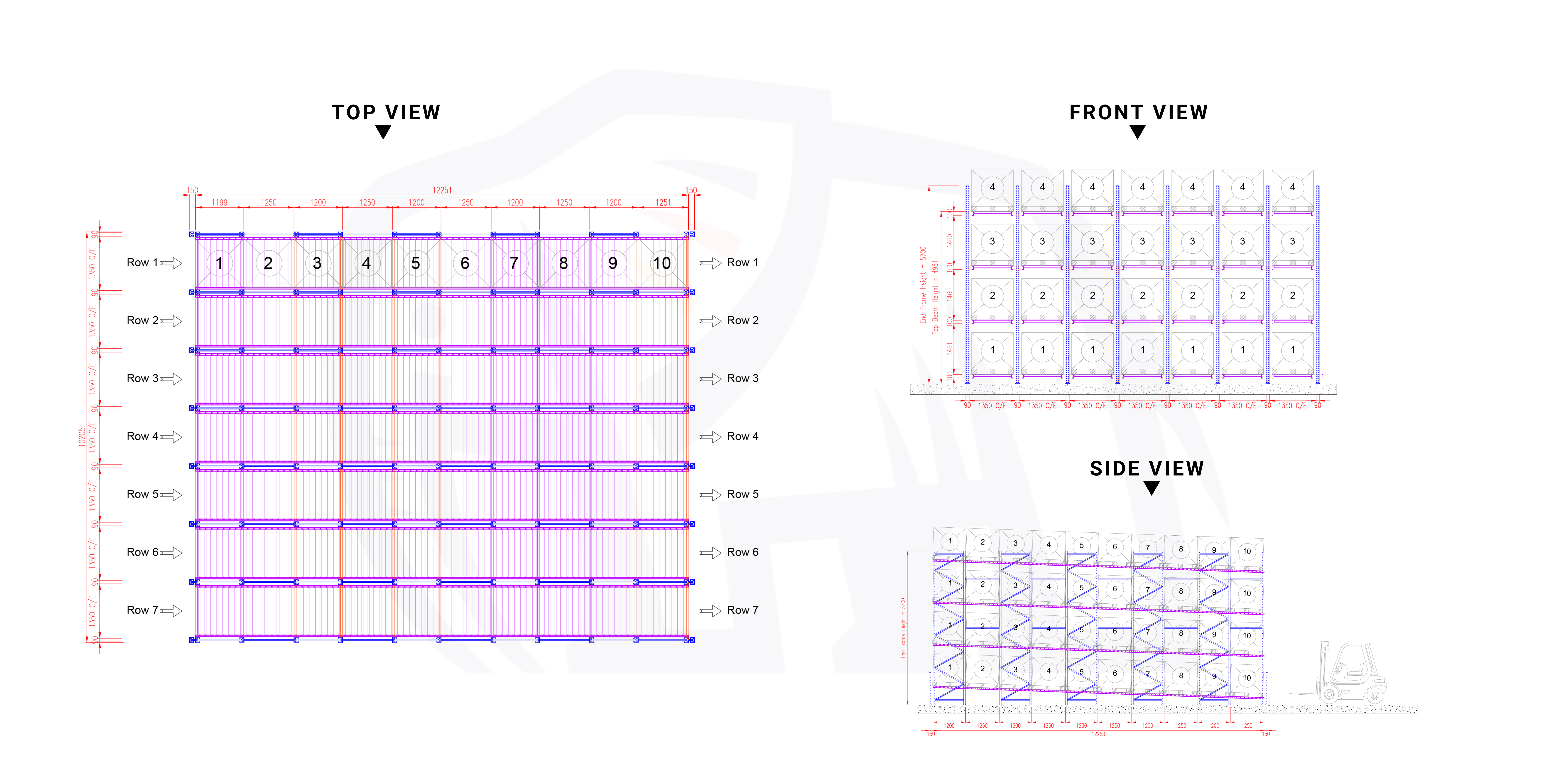

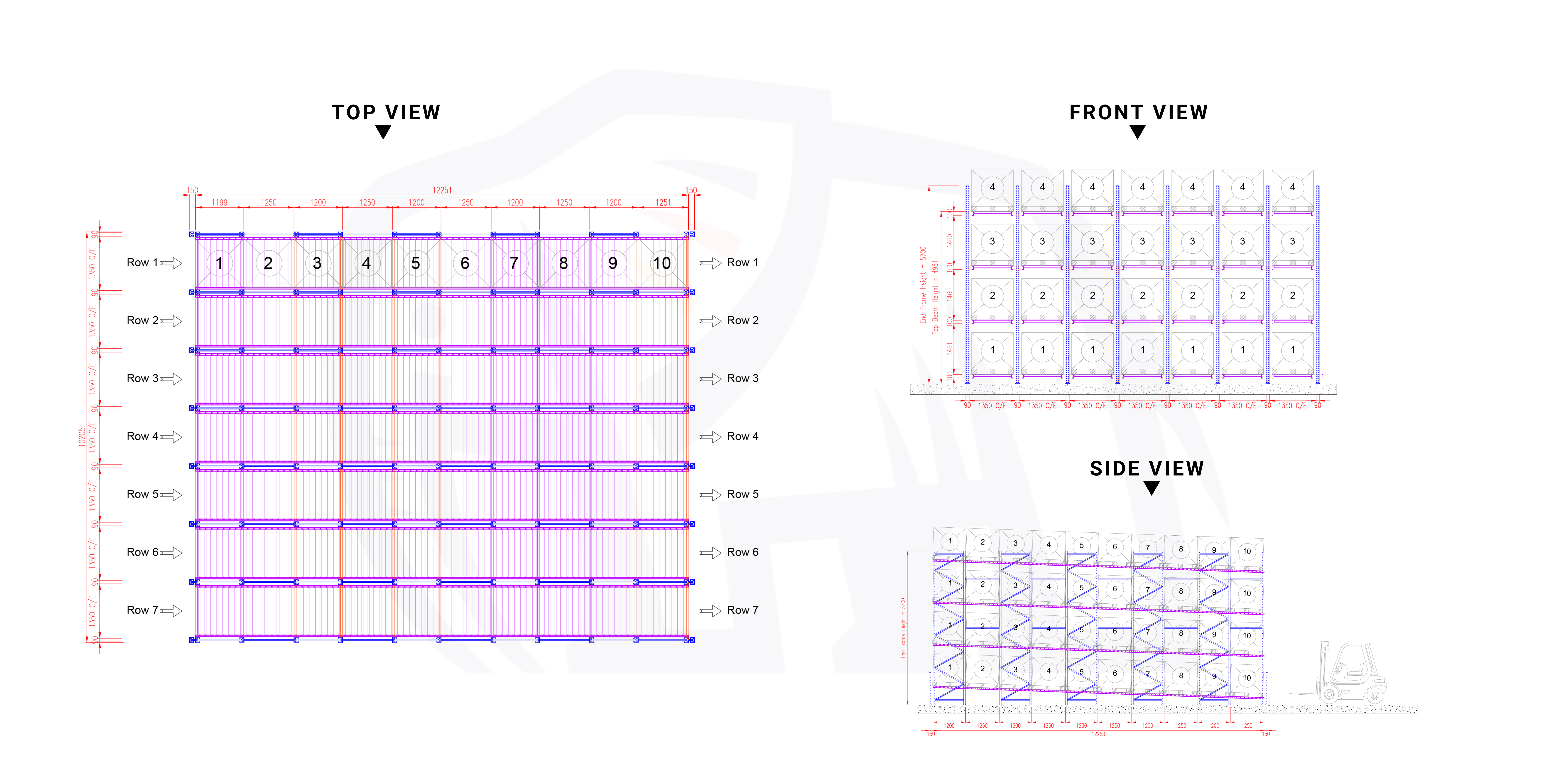

- Expertise: We dive deep into your warehouse space to determine the best racking configurations tailored to your needs.

- High-Tech Solutions: Our AutoCAD designs maximize storage while ensuring your team has ergonomic access to what they need.

- Side-by-Side Comparisons: Our planning process allows you to compare layout options easily, helping you make informed decisions.

- Data-Driven ROI Calculation: We provide detailed numerical data for each layout, empowering you to understand the impact on your bottom line.

- Customization: Our custom racking systems are built to meet your unique requirements, ensuring the best approach for your facility.