What is a Selective Racking System?

- 15/11/2024

- Posted by: macgad-admin

- Category: Racking System

What is a Selective Racking System?

Selective racking systems rank among the most popular warehouse storage options due to their simplicity and effectiveness. In fact, a survey of warehouse managers revealed that nearly 60% prefer selective racking for its accessibility and cost-efficiency. Therefore, this article explores what selective racking systems are, how they work, and why they’re an excellent choice for boosting warehouse productivity.

How Does a Selective Racking System Work?

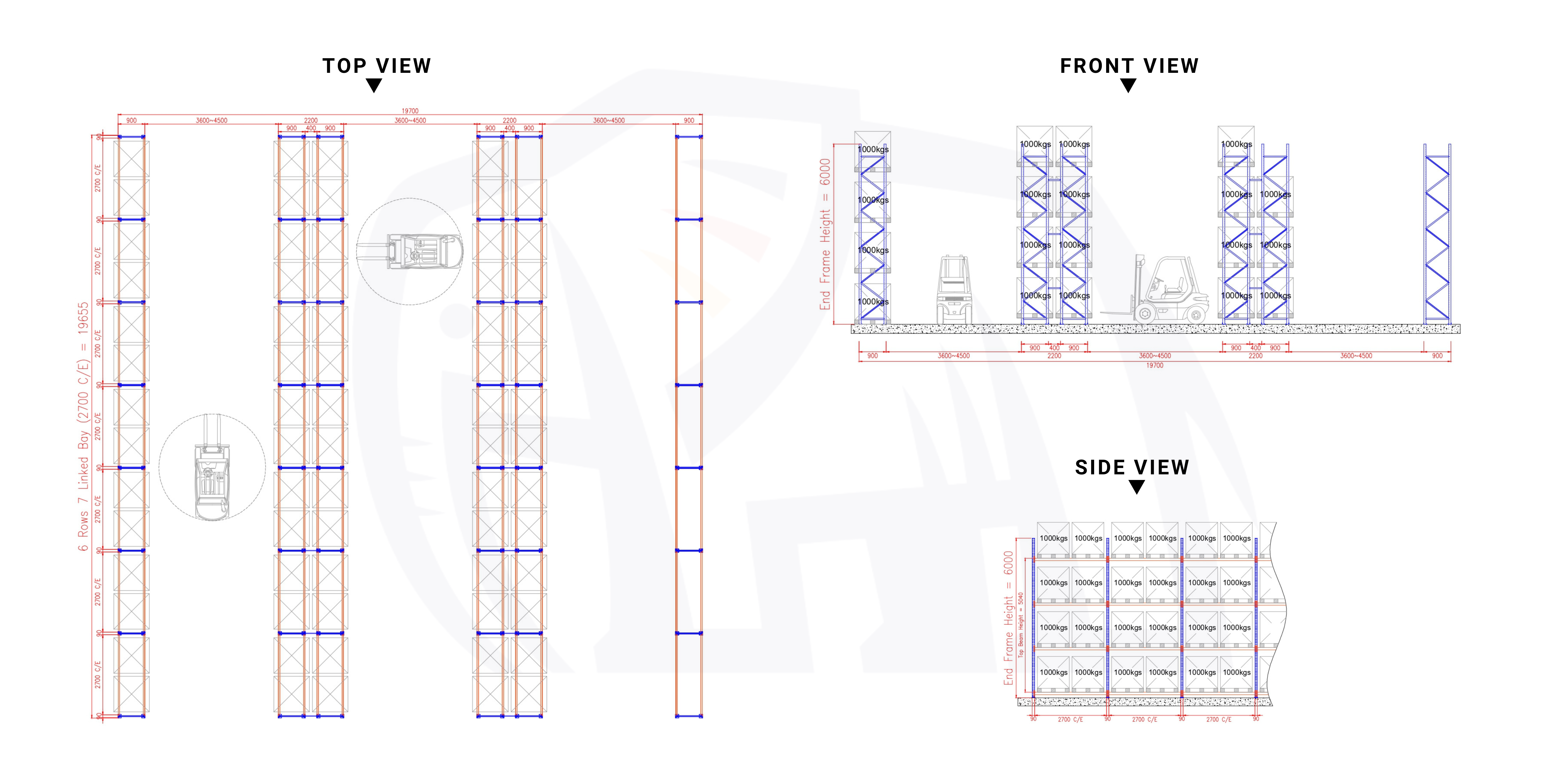

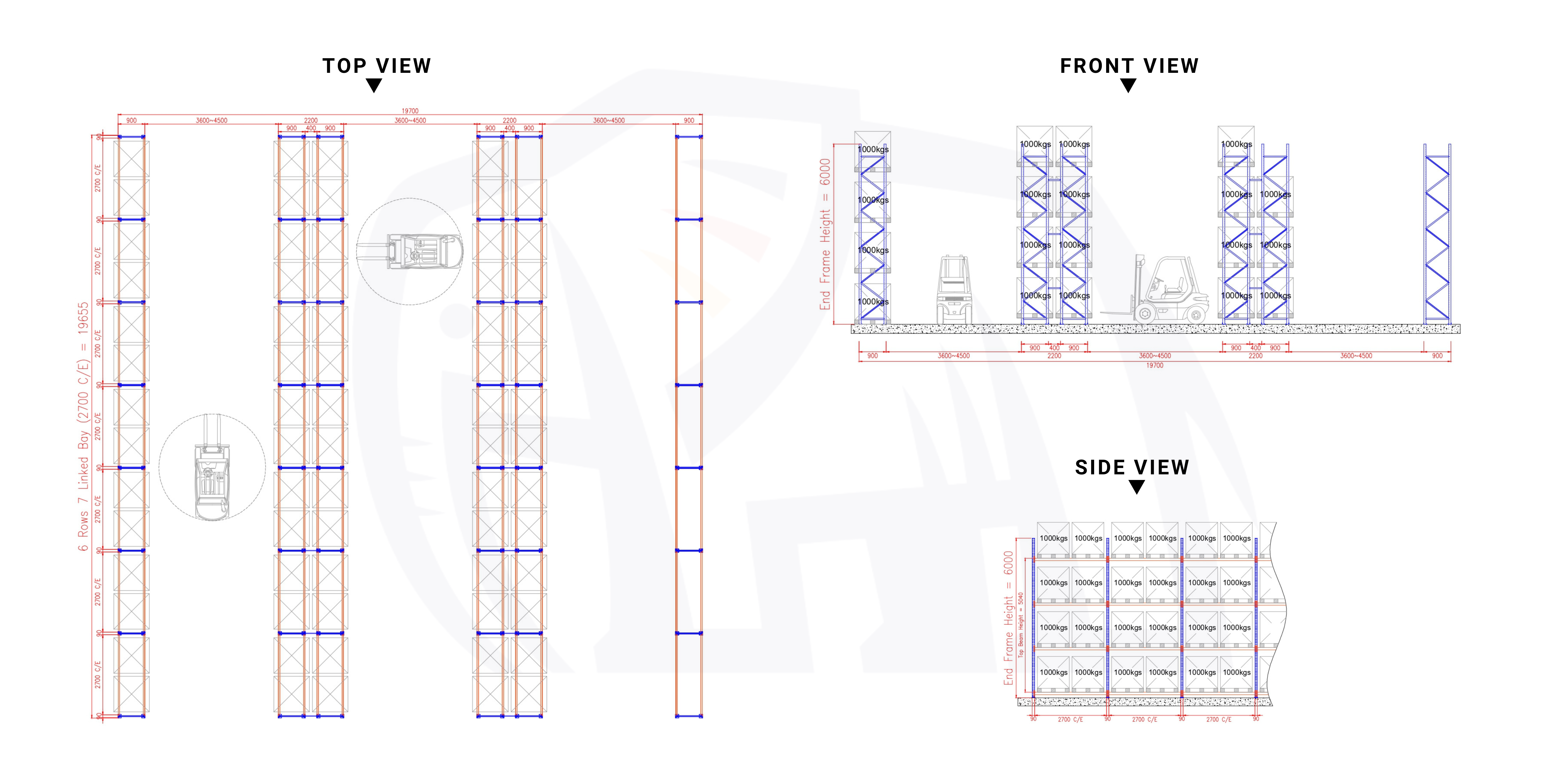

To begin with, selective racking systems allow direct access to each pallet, enabling forklifts to easily retrieve items without moving others. The system typically consists of upright frames and horizontal beams, which form rows for pallet storage. For example, if you need a product located in the middle of a full storage bay, selective racking lets you access it directly, significantly speeding up operations.

Additionally, selective racking works with standard forklifts, which can save businesses up to 20% in equipment costs. As a result, this compatibility makes the system not only efficient but also cost-effective.

Benefits of a Selective Racking System

Selective racking systems offer several benefits that make them suitable for various warehouse operations:

- Full Accessibility: Workers can access any pallet at any time, which makes this system ideal for facilities with high inventory turnover. In fact, studies show that warehouses using selective racking can achieve 25% faster picking times.

- Cost-Effective: With a straightforward design, selective racking typically costs less to install and maintain. In many cases, initial setup costs can be as low as $50 per pallet location, depending on warehouse size and material choices.

- Scalable and Adaptable: Moreover, selective racking can reconfigure as needs change. This flexibility helps businesses manage seasonal inventory or fluctuating stock volumes.

- Compatible with Standard Forklifts: Lastly, the system is designed to work with various forklifts, making it easy to integrate and less costly to operate.

When to Use Selective Racking Systems?

Selective racking shines in warehouses that handle diverse inventory and require flexible storage. Common use cases include:

- Warehouses with High SKU Variety: Businesses that store numerous different products benefit from easy access and high selectivity.

- Operations with High Turnover Rates: Furthermore, selective racking allows quick access to products, reducing labor costs. Warehouses with this system often see 15% faster retrieval times.

- Warehouses with Limited Floor Space: In addition, selective racking maximizes vertical storage, potentially increasing storage capacity by up to 40% compared to traditional shelving.

Selective Racking System vs. Other Racking Systems

When evaluating storage options, it’s useful to compare selective racking to other popular systems:

- Selective vs. Drive-In Racking: While drive-in racking can store 75% more pallets in the same footprint, it requires pallets to load and unload in a specific order (Last-In, First-Out). In contrast, selective racking allows free access to any pallet, making it more suitable for varied SKU storage.

- Selective vs. Pallet Flow Racking: On the other hand, pallet flow racking supports high-density storage and suits First-In, First-Out (FIFO) needs, but it typically costs more to install. Thus, selective racking strikes a balance between accessibility and affordability.

Installation Guide for a Selective Racking System in 2024

Proper installation ensures efficiency and safety in a selective racking system. Here’s a quick guide for a smooth setup:

- Plan Your Layout: First, measure the available space, including aisle widths for safe and efficient forklift movement.

- Calculate Load Capacity: Next, confirm that the system’s load capacity matches the weight and size of your pallets. Overloading can lead to costly repairs and safety risks. Typically, selective racks support 1,000 to 6,000 pounds per beam level.

- Secure the Frames: Afterward, anchor the racking frames to the warehouse floor to ensure stability, especially when storing heavy loads.

- Ensure Proper Aisle Spacing: Finally, maintain recommended aisle widths based on forklift type. Standard forklifts usually require 10-12 feet wide aisles, while narrow aisle forklifts can operate in 6-8 feet.

Cost of Installing a Selective Racking System?

The cost to install a selective racking system varies widely based on warehouse size, material choice, and local labor rates. On average, businesses spend $100-$200 per pallet position for selective racking, making it one of the more affordable options. Consequently, the benefits—like faster retrieval times and optimized space—can help offset installation costs, delivering a significant return on investment through improved productivity.

Best Selective Racking System Provider?

Selecting a reputable provider is essential for ensuring the quality and safety of your selective racking system. Here are some key tips to guide your choice:

- Research Local Suppliers: Start by looking for suppliers with a solid reputation and extensive experience in racking systems. Customer reviews and testimonials can provide valuable insight into their service quality and reliability.

- Check Certifications: Ensure the provider complies with industry standards and safety regulations. Certified suppliers are often more dependable and offer higher quality products.

- Evaluate Customer Support: A great provider should deliver excellent customer service. Look for companies that offer comprehensive consultation, installation support, and after-sales service, ensuring you’re not left in the lurch after your purchase.

- Compare Pricing and Warranties: Always get quotes from multiple providers to find the best price. Don’t forget to review warranty terms to safeguard your investment for the long run.

Ready to take the next step? At HYPERACK, we specialize in selective racking systems tailored to your needs. Contact us today for a free consultation and let our experts help you optimize your warehouse storage solution! Explore our social media to see real-life projects in action.

Conclusion

In summary, selective racking systems provide a simple, flexible, and affordable solution for many warehousing needs in 2024. They suit operations requiring fast, direct access to diverse SKUs, making them an excellent choice for warehouses aiming to balance cost with efficiency.