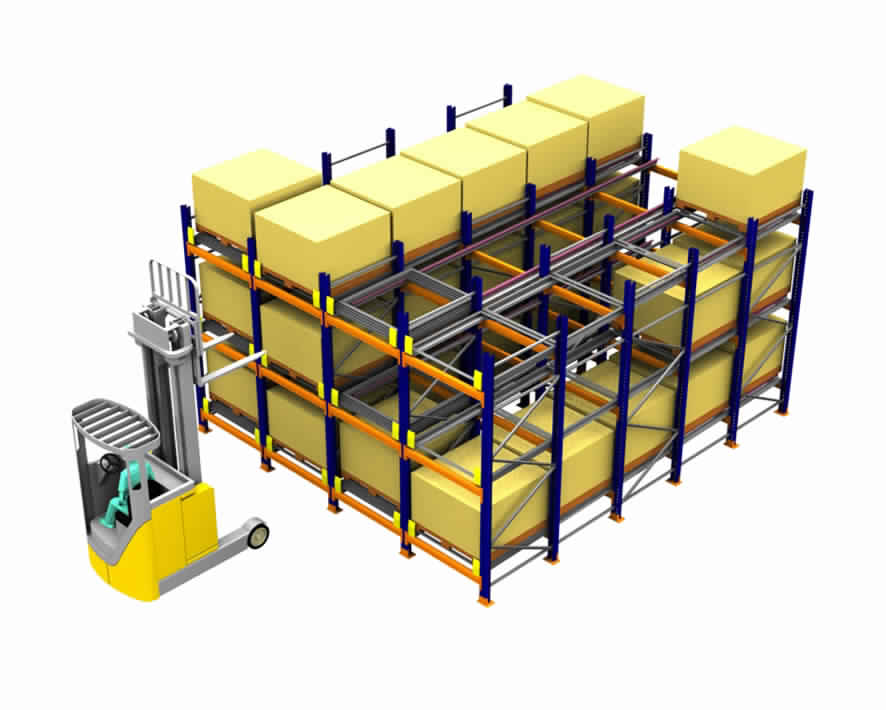

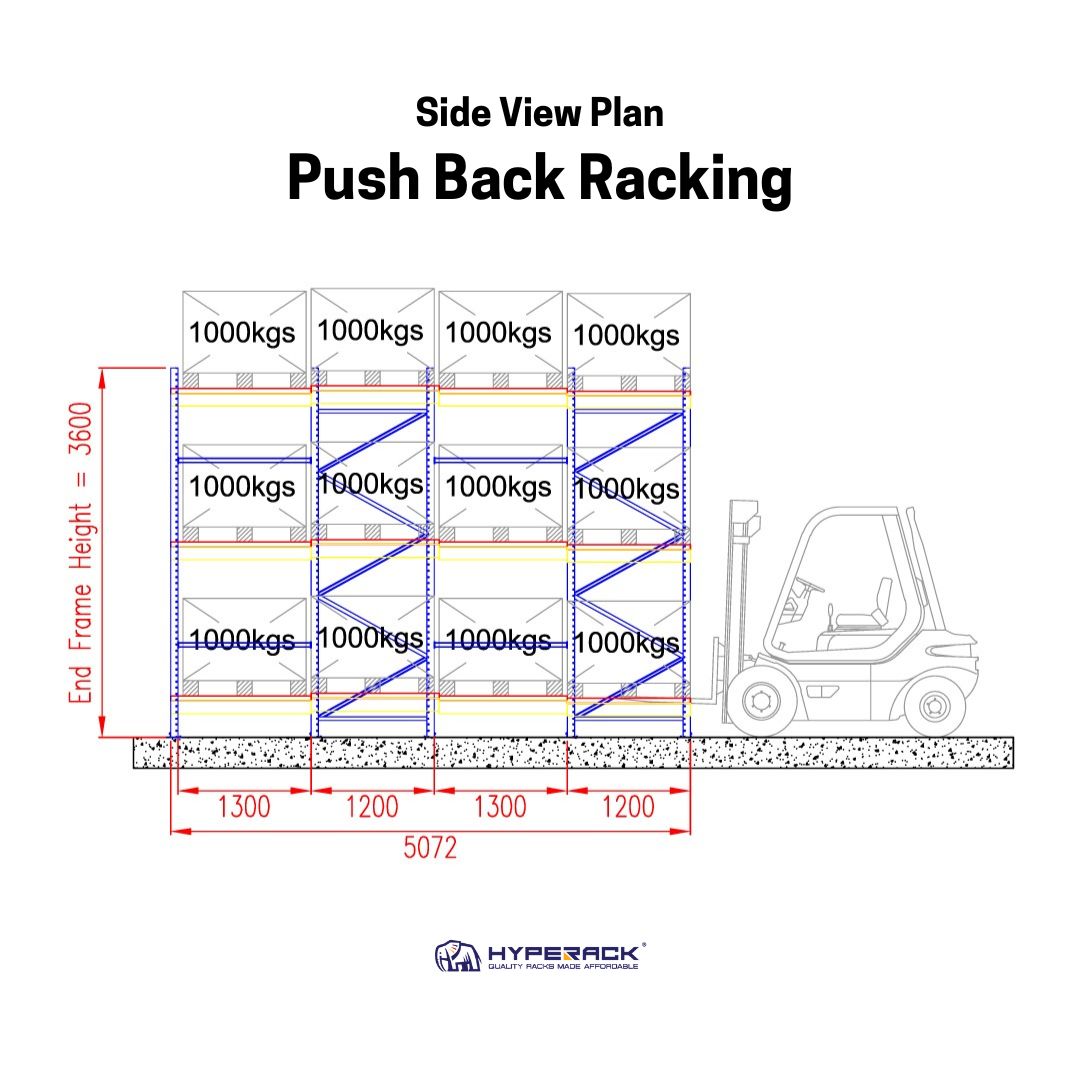

Push Back Pallet Racking systems are designed to optimize warehouse storage and enhance efficiency. In these systems, pallets are loaded from the front, which pushes the pallets behind them back by one position. When it’s time to unload, the front pallet is removed, and the rear pallets automatically advance to the front picking position. This dynamic ensures a smooth flow of goods and reduces handling time.

Push Back Pallet Racking is famous for its high-density storage capability. Unlike traditional racking systems, which require separate aisles for access, Push Back Pallet Racking consolidates storage into compact lanes. This space-saving approach allows for multiple pallets to be stored in a single lane, significantly maximizing warehouse capacity.

Moreover, Push Back Pallet Racking is ideal for handling various types of products, especially those that are stored in bulk. The system supports first-in, last-out (FILO) inventory management, which is beneficial for products with longer shelf life or those that do not require frequent rotation.