Products

Pallet Tainer

A pallet tainer is a strong, industrial container made to improve how you store and move items. Made from durable materials like plastic or metal, these containers fit neatly on a standard pallet, making them perfect for industries like agriculture, manufacturing, and logistics.

Pallet tainers help you get more out of your warehouse. They keep products safe from damage and dirt, and their stackable design makes it easy to use your storage space efficiently. Plus, pallet tainers are simple to move with forklifts or pallet jacks, making transport a breeze.

At Hyperack, we offer a great selection of pallet tainers that are built to handle tough warehouse and logistics demands. Our containers are durable and designed to work well, helping you improve your warehouse efficiency.

Ideal for

- Storing and moving bulk agricultural products like grains and vegetables

- Organizing and transporting parts and materials for manufacturers

- Efficient logistics warehousing and distribution of goods

Advantages

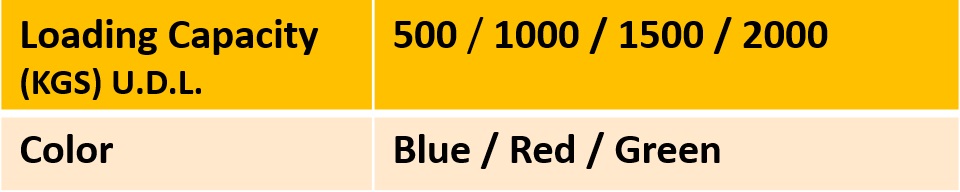

- Made from metal, built to last and withstand heavy use

- Provides a safe, enclosed space for your items, protecting them from damage and contamination

- Stackable design helps maximize warehouse space

- Can be easily moved with forklifts or pallet jacks, streamlining your transportation process

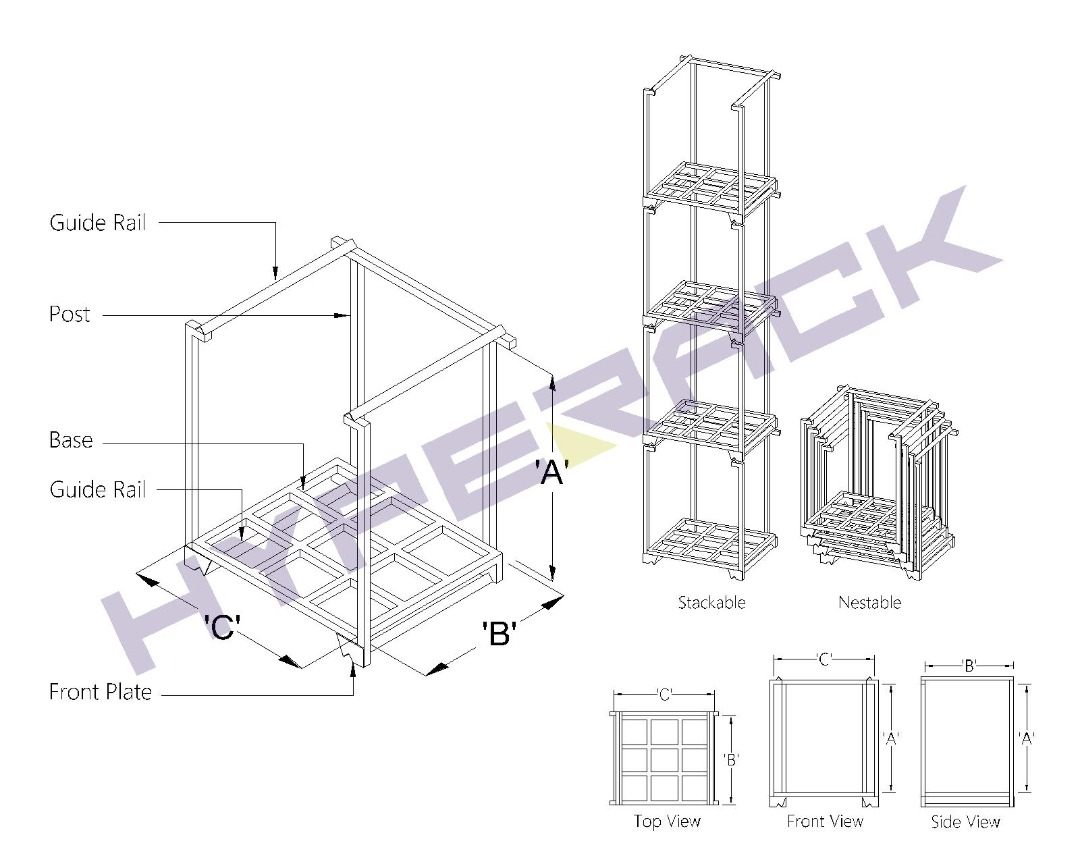

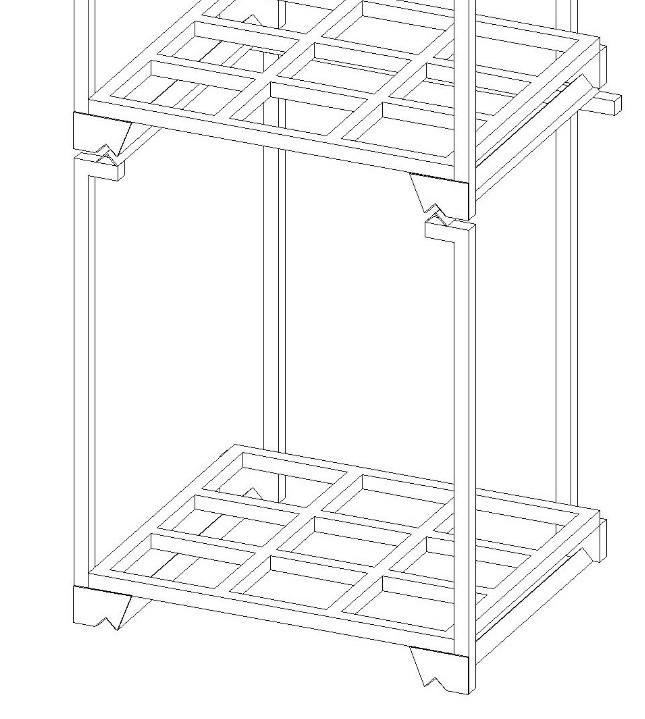

Self-guided Stacking

The Pallet Tainer exclusive inverted angles provide safe, secure and simple stacking. By positioning the bottom angles of the top rack over the stacking tubes of the unit below, the Pallet Tainer rack can be guided into it’s stacked position for full column-to-column loading. Self-guided stacking does away with the trial and error method of post and target stacking.

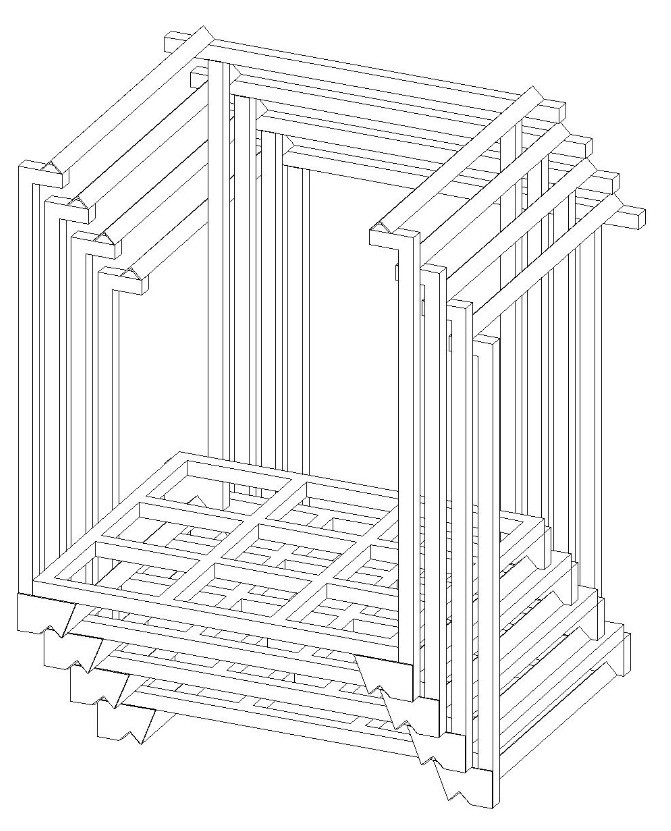

Front-end Nesting

Pallet tainer front-end nesting increases empty rack handling and efficiency. Each rack adds only 5½ inch to the overall nested height and overhang is limited to 2 inch per tainer. This results in nesting ratios as great as 12:1, depending on tainer height and depth, and allows rack tainer nesting in low overhead areas. Pallet Tainer nests can besily handled with a handling material equipment such as reach truck, forklift and pallet jack.

5 Easy Steps

1. Enquiry

Your journey begins with a simple enquiry. Once we receive your request, our team will review the details and match you with the right expert. We’ll then arrange a quick call or email to learn more about your goals and expectations.

2. Free Consultation

After your initial consultation, we’ll arrange a site visit to assess your space and needs in detail. You’ll meet your dedicated project manager, who will guide the process from start to finish—ensuring everything runs smoothly and efficiently.

3. 3D CAD Design

After the site survey, your project manager will recommend layout options tailored to your space and needs. We’ll then create accurate 3D CAD designs to help you visualise exactly how your facility will look once complete.

4. Instant Quote

You’ll receive a free, personalised quote with a full breakdown of the recommended equipment. We offer high-quality products at competitive prices, with reliable delivery times to keep your project on schedule.

5. Installation

We’ll agree on an installation schedule that suits your operations. Our accredited team will complete the setup, conduct a final inspection with you, and provide follow-up support, including annual safety checks.

Ready to make a change?

We are here to help you choose the best racking for your business. Schedule a call with our representative today.

FAQ

What industries benefit the most from using Pallet Tainers?

Pallet Tainers are widely used across various industries, including:

- Agriculture: To store and transport bulk products like grains, vegetables, and fruits.

- Manufacturing: For organizing and shipping parts and raw materials.

- Logistics and Warehousing: To streamline the storage and distribution of goods, making it easier to handle large volumes of inventory.

These industries the most benefit from Pallet Tainers due to their durability, stackability, and efficient use of space, improving overall operational efficiency but it is generally best used for any industry.

Why should I use Pallet Tainers instead of regular pallets for storage?

Pallet Tainers offer several key advantages over regular pallets:

- Enhanced Protection: The enclosed design keeps items safe from damage, dust, and contamination.

- Stackability: You can stack Pallet Tainers, which maximizes vertical storage space in your warehouse.

- Durability: Made from high-quality materials, they last longer under heavy-duty use.

- Easy Handling: Designed for use with forklifts, making movement within warehouses efficient.

How do Pallet Tainers help businesses save on warehouse space?

The stackable design of Pallet Tainers allows businesses to use vertical space in their warehouses more effectively. This is particularly useful in environments where maximizing storage capacity is a priority, such as in logistics, manufacturing, and distribution. By storing items in these containers, businesses can improve organization and reduce clutter in the warehouse.

Are Pallet Tainers suitable for outdoor use in Malaysia’s tropical climate?

Yes, Pallet Tainers made from galvanized steel or plastic are resistant to corrosion and are suitable for outdoor storage. However, it is advisable to protect them from extreme weather conditions such as heavy rain, especially in Malaysia’s humid climate, to prolong their lifespan. You can use protective covers or store them in sheltered areas for better protection.

What factors should I consider when choosing the right Pallet Tainer for my warehouse?

When selecting a Pallet Tainer, keep in mind:

- Material: Choose between plastic or metal based on the weight and nature of your goods.

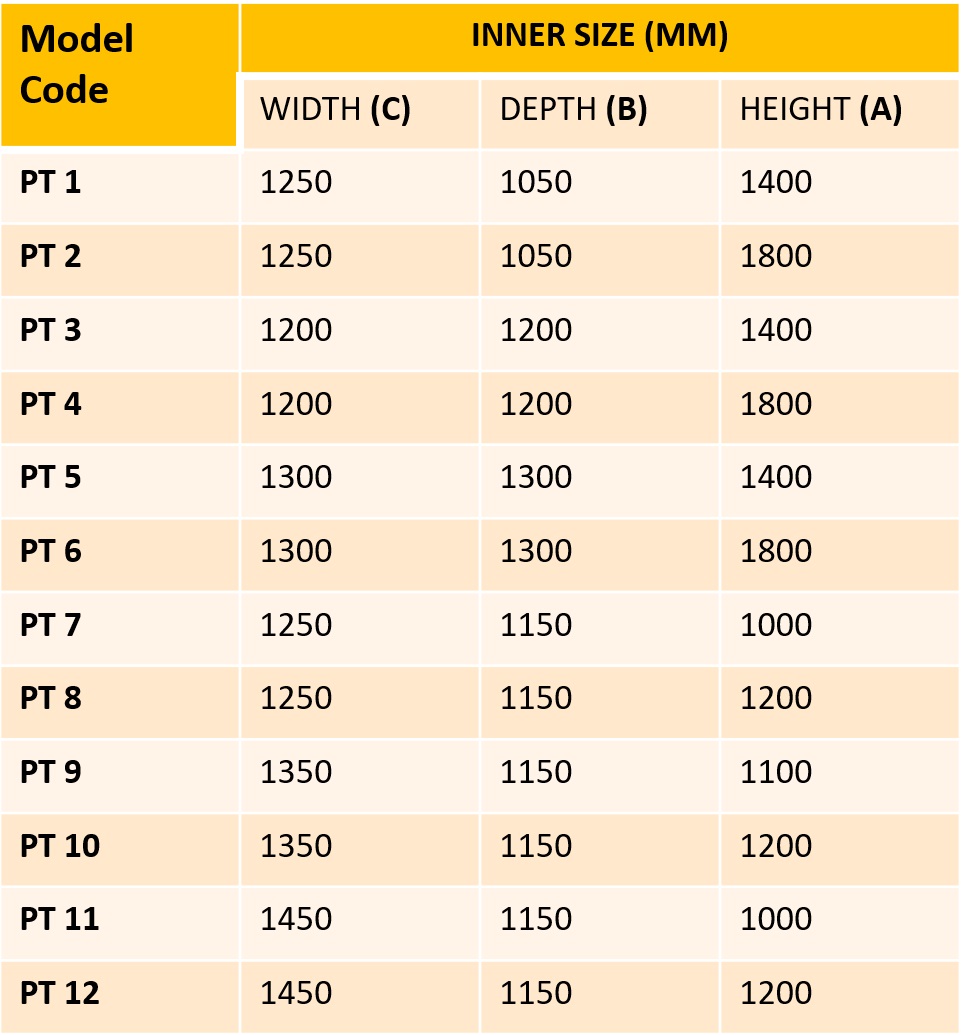

- Size: Ensure the tainer fits your products and is compatible with your warehouse shelving.

- Weight Capacity: Consider the load each tainer can handle to avoid overloading.

- Stackability: Ensure the tainer’s design allows for safe stacking to optimize space in your warehouse.

What materials are Pallet Tainers made from, and how do they compare to traditional pallets?

Pallet Tainers are usually made from tough plastic or metal, which makes them more durable than your usual wooden pallets. They’re not only more resistant to damage like splinters or moisture but also way easier to maintain. Plus, they’re a lot more eco-friendly in the long run compared to traditional pallets.

Can Pallet Tainers be customized to fit specific product dimensions or warehouse requirements?

Absolutely! Pallet Tainers can be tailored to meet your exact needs. Whether it’s a specific size, extra reinforcements, or added features like locks or dividers, you can get them just right for what you need to store.

How do Pallet Tainers help reduce product damage during storage and transportation?

Thanks to their sturdy design, Pallet Tainers keep your products in place, preventing them from shifting or getting damaged. They’re also sealed, so they keep your goods safe from dust, dirt, and anything that might cause harm during transport.

What’s the lifespan of a Pallet Tainer compared to regular pallets?

A Pallet Tainer can last a lot longer than a regular wooden pallet. With proper care, you’re looking at many years, even decades, of service. That makes them a smart investment, especially since you won’t have to keep replacing them like you might with wooden pallets.

Can Pallet Tainers be used with automated warehouse systems and equipment?

Definitely! Pallet Tainers are designed to fit right into automated warehouse setups. They work perfectly with conveyors, forklifts, and even robots, which means less manual labor and more efficiency in your warehouse.