Warehouse racking

Double-Deep Pallet Racking System

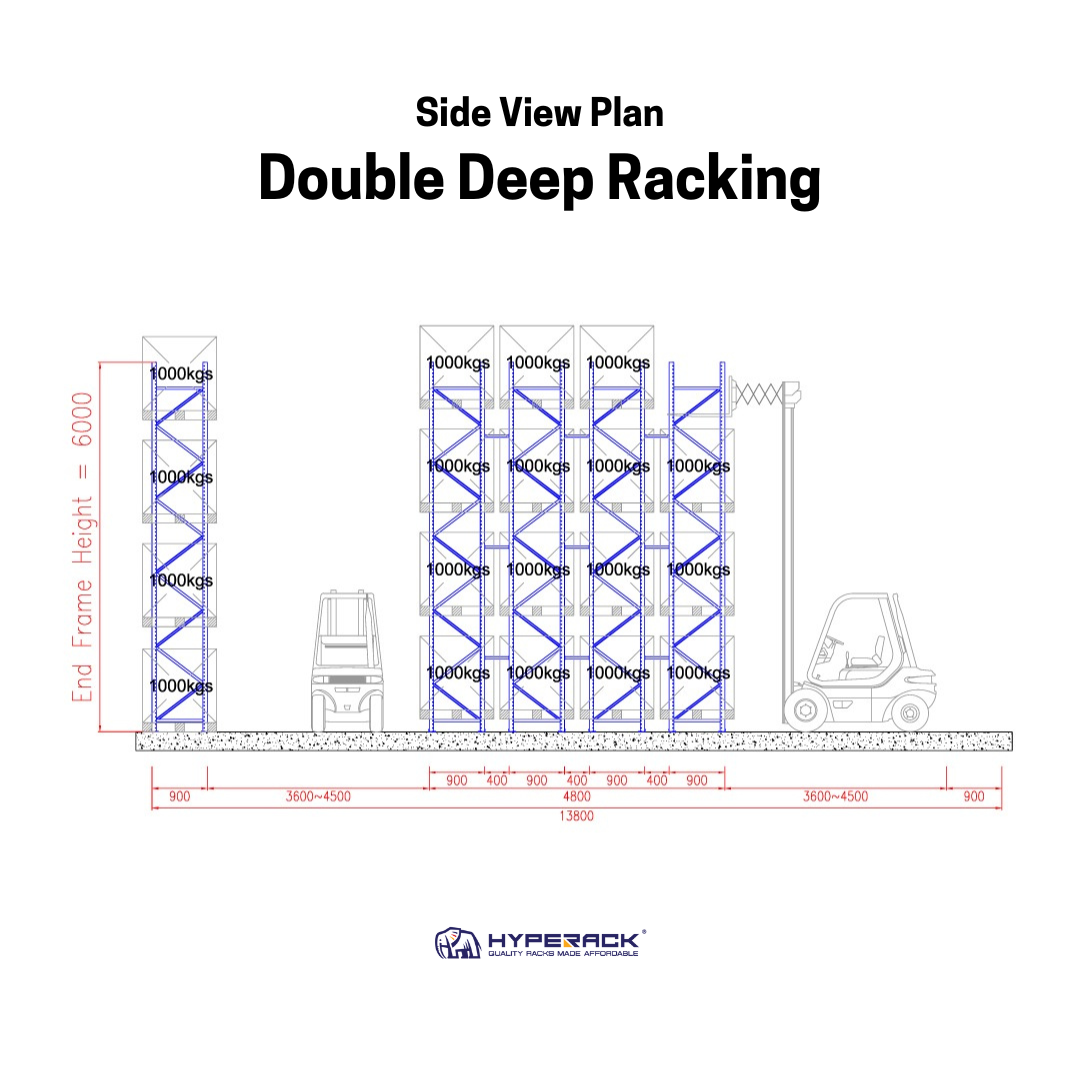

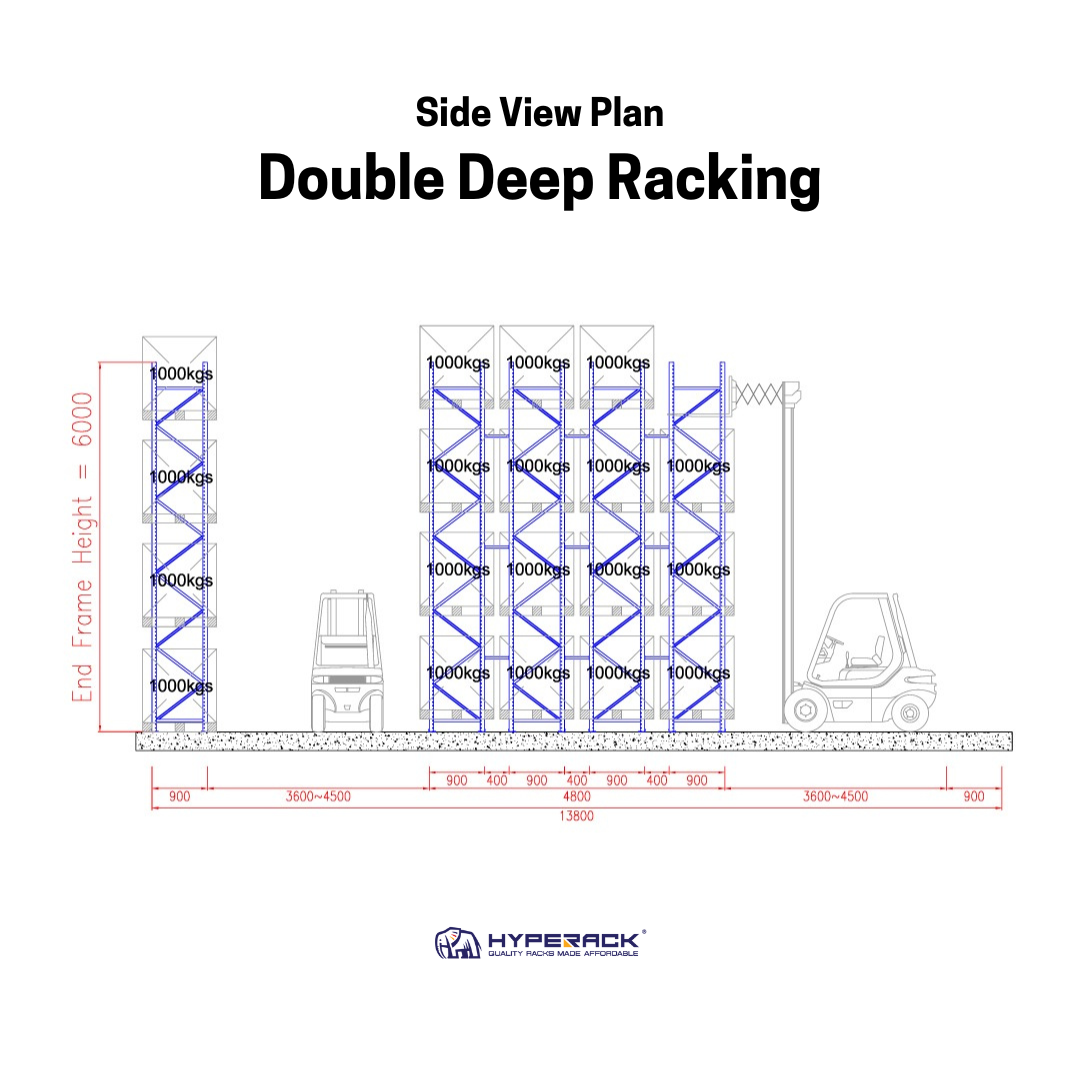

The Double Deep Racking system is a high-density storage solution designed to maximize warehouse space by allowing pallets to be stored two deep within each racking bay. This innovative racking system effectively doubles the storage capacity compared to standard pallet racking setups, making it an ideal choice for warehouses with high-volume inventory needs.

To operate a Double Deep Racking system efficiently, specialized pallet handling equipment is essential. Warehouses can utilize either a specialized forklift designed specifically for Double Deep Racking or a standard forklift equipped with a double deep handling attachment. This equipment allows for precise access and retrieval of pallets stored in the deeper sections of the racking system, ensuring smooth and efficient warehouse operations.

Overall, Double Deep Racking offers a strategic solution for warehouses aiming to optimize their storage capacity and operational efficiency. By investing in the right equipment and proper training, businesses can fully leverage the benefits of this advanced racking system.

Ideal for

- High Density Storage - maximizing cubic space

- Reduces aisles space increases cubed space utilization

- When alternative systems such as the Drive-In Racking are not possible

Advantages

- 30% more space than Selective pallet racking

- Lower cost than Drive-In Racking, while increasing capacity by up to 30%

- Doesn’t require a high number of homogenous pallet types

5 Easy Steps

1. Enquiry

Your journey begins with a simple enquiry. Once we receive your request, our team will review the details and match you with the right expert. We’ll then arrange a quick call or email to learn more about your goals and expectations.

2. Free Consultation

After your initial consultation, we’ll arrange a site visit to assess your space and needs in detail. You’ll meet your dedicated project manager, who will guide the process from start to finish—ensuring everything runs smoothly and efficiently.

3. 3D CAD Design

After the site survey, your project manager will recommend layout options tailored to your space and needs. We’ll then create accurate 3D CAD designs to help you visualise exactly how your facility will look once complete.

4. Instant Quote

You’ll receive a free, personalised quote with a full breakdown of the recommended equipment. We offer high-quality products at competitive prices, with reliable delivery times to keep your project on schedule.

5. Installation

We’ll agree on an installation schedule that suits your operations. Our accredited team will complete the setup, conduct a final inspection with you, and provide follow-up support, including annual safety checks.

Ready to make a change?

We are here to help you choose the best racking for your business. Schedule a call with our representative today.

FAQ

Double Deep vs Selective (Single Deep) Racking: What's the Difference?

The key technical difference between Double Deep and Selective (Single Deep) Racking lies in their storage layout and accessibility. In Double Deep Racking, pallets are stored two rows deep, which maximizes space utilization but limits direct access to each pallet. This system requires specialized equipment, such as a double-deep reach truck, that can extend to the second row. Selective Racking, on the other hand, allows for direct access to every pallet, making it more flexible but less space-efficient. Selective racks typically have wider aisles, resulting in more floor space usage.

What type of forklift is required for Double Deep Racking?

A specialized forklift, often a double-deep reach truck, is required for Double Deep Racking systems. These trucks are equipped with a pantograph mechanism, allowing the operator to reach over the first row of pallets to retrieve or store items in the second row. The truck’s lifting capacity, reach, and maneuverability are crucial for efficiently accessing deep storage without damaging products or racks. In addition, the truck must be capable of navigating the narrower aisles typical of Double Deep Racking setups.

How does stock rotation work in a Double Deep Racking system?

Stock rotation in a Double Deep Racking system is typically based on the First-In, First-Out (FIFO) method, which is essential for perishable or time-sensitive products. The system’s design ensures that the first pallets placed in the racking are the first to be retrieved. However, to maintain effective stock rotation, it’s crucial to monitor and manage the flow of goods in and out of the system. Due to the deeper storage in Double Deep Racking, operators often rely on specialized forklifts with extended reach capabilities and may incorporate automated systems to streamline the rotation process and avoid manual errors.

What industries benefit most from Double Deep Racking?

Double Deep Racking is particularly beneficial for industries such as:

- Retail and Wholesale Distribution: High-volume, uniform pallet storage with relatively low SKU variety.

- Manufacturing: Large-scale inventory of raw materials or finished goods that do not require constant access.

- Food and Beverage: For bulk storage of non-perishable products that need to be organized efficiently. The system is ideal for businesses with substantial warehouse space that need to maximize storage capacity while maintaining efficient, albeit less direct, access to products.

What are the safety considerations for using Double Deep Racking systems?

Safety is a key consideration when implementing a Double Deep Racking system. Operators must be trained to operate double-deep reach trucks safely, ensuring they can navigate narrow aisles and retrieve pallets from the deeper sections without causing damage to the racks or inventory. Other technical safety measures include:

- Load Capacity: Ensuring that each rack and forklift is rated for the appropriate weight load.

- Rack Inspections: Regularly inspecting beams, uprights, and connectors for wear or damage due to heavy loads or forklift impacts.

- Pallet Positioning: Ensuring that pallets are stored correctly to avoid instability, especially in the deeper sections of the racking.

How does the access to the second pallet work in Double Deep Racking systems?

- Specialized Forklifts: To access the second pallet, operators use reach trucks equipped with a telescoping or double-deep reach mechanism. These forklifts are designed to retrieve the second pallet without moving the first.

- Accessing the Second Pallet: The forklift first picks up the front pallet (usually positioned in a way that it can be easily moved) and then slides the second pallet from behind it. The forklift can also push or pull pallets using the double-deep forks to position them for picking.

- Cycle Time: The time it takes to retrieve the second pallet can be longer than for standard selective racking due to the need to maneuver the forklift and possibly move the front pallet.

- Stock Management: Efficient stock management practices like FIFO (First In, First Out) or LIFO (Last In, First Out) ensure that stock is rotated properly, and the second pallet is accessed in a timely manner when needed.

What are the potential downsides or challenges of using Double Deep Racking?

- Limited Access to Second Pallet: Accessing the second pallet in double deep racking requires specialized equipment, typically a reach truck with a double-deep reach capability. This can slow down picking operations if not properly managed.

- Reduced Visibility: Since the second pallet is stored behind the first, it can be harder to monitor inventory levels or access products quickly without a systematic approach to stock management.

- Space Efficiency: While double deep racks offer more storage density, they can reduce aisle space and maneuverability for forklifts, especially in narrower aisles.

- High Initial Costs: The initial setup cost can be higher due to the need for specialized equipment and the design of the system.

- Complex Stock Rotation: Managing stock rotation (FIFO or LIFO) can become more complicated, requiring careful planning and tracking to avoid stock becoming obsolete.

How do you handle damaged pallets in a Double Deep Racking system?

- Immediate Removal: As soon as a damaged pallet is identified, it should be removed to prevent the damage from affecting other products and to maintain safety.

- Inspection and Repair: Inspect the pallet thoroughly to determine if it can be repaired (e.g., replacing damaged slats or frames). Ensure that the repairs meet safety standards.

- Replacement: If the pallet is beyond repair, replace it immediately to maintain the integrity of your racking system.

- Document Damage: Keep records of damaged pallets for quality control and to ensure any recurring issues are addressed with suppliers or during inventory management.

- Safety Checks: Regularly check racks and forklift operations to minimize further damage to pallets, as improper handling can contribute to more damage.

Are there any environmental considerations when installing Double Deep Racking in a warehouse?

- Energy Efficiency: Consider the impact of lighting and heating in areas with double deep racking, as taller racks can create dark spaces and may affect heating distribution. Install energy-efficient lighting and temperature regulation to minimize energy use.

- Ventilation and Airflow: Ensure proper airflow in the warehouse to avoid the buildup of moisture, especially in cold storage areas. Double deep racking systems can limit air circulation, so it’s important to design the layout with adequate space between racks.

- Recycling and Sustainability: Use eco-friendly materials for the racking systems where possible. Opt for recyclable metals or materials, and ensure that damaged racks are properly recycled.

- Warehouse Material Handling: Evaluate whether your forklifts and material handling equipment are energy-efficient and designed for the heavier lifting needs of a double deep system.

What are the best practices for organizing and labeling pallets in Double Deep Racking systems?

- Label Clearly: Use large, clear labels that include product information such as SKU, batch number, and expiration date (if applicable). Place labels on the front and side of the pallet for easy identification.

- Group Similar Products: Organize pallets by product type or SKU in the same section to streamline picking and reduce errors.

- Implement Color Coding: Use color-coded labels or tags to indicate stock priority, product type, or location for faster identification and access.

- FIFO or LIFO: Depending on your inventory system, ensure pallets are organized for FIFO (First In, First Out) or LIFO (Last In, First Out) rotation to maintain stock accuracy.

- Regular Audits: Periodically check the condition of the pallets, especially if stock is stored for long periods, to ensure proper organization and avoid bottlenecks.