Warehouse racking

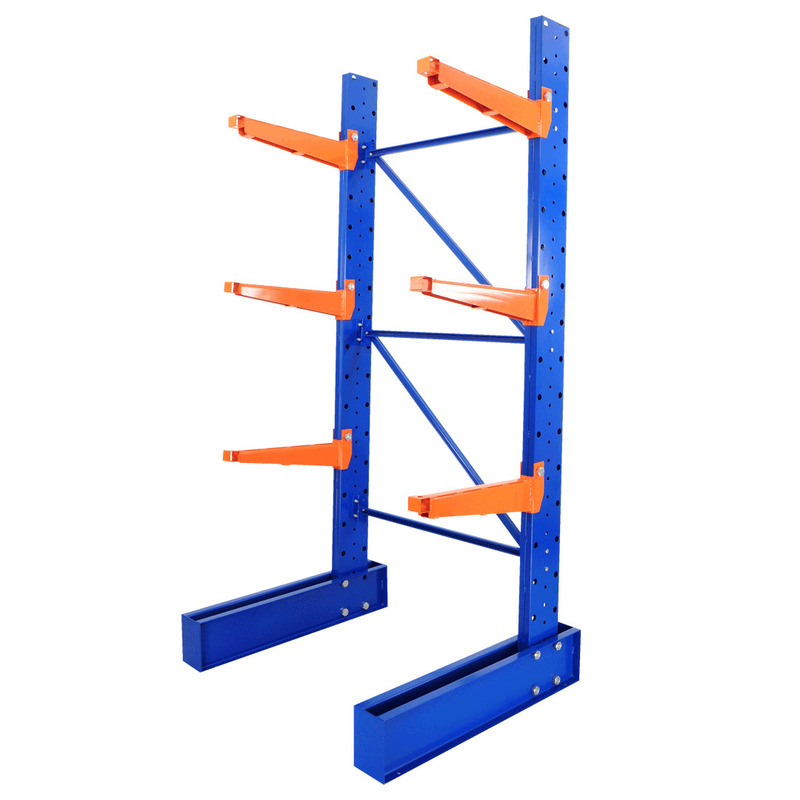

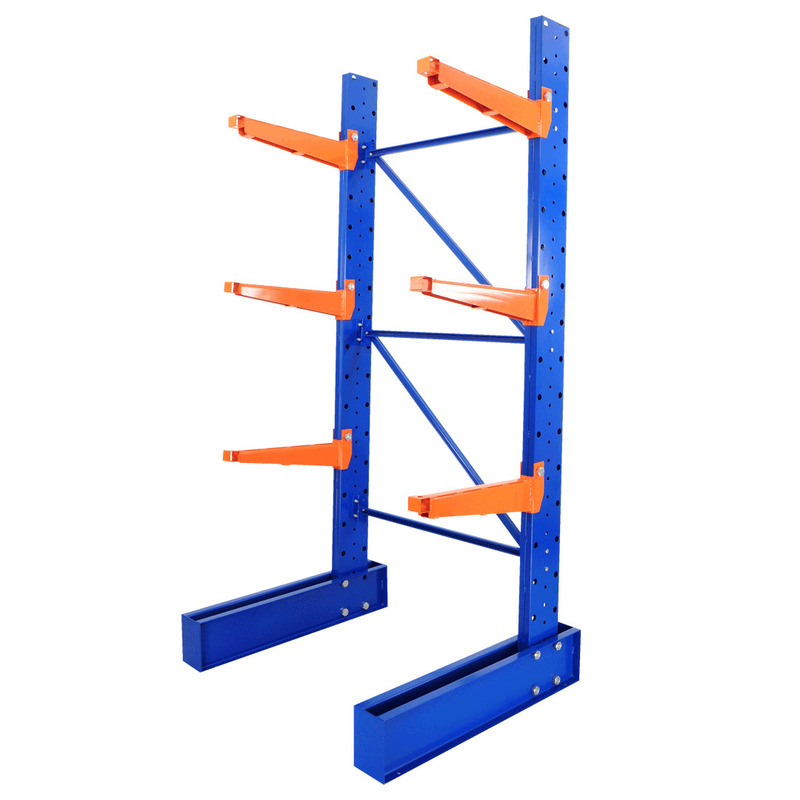

Cantilever Racking

The Hyperack Cantilever Racking System is the ultimate solution for storing challenging, long, and heavy items such as steel bars, pipes, tubes, packs of timber, or furniture. Designed to handle items that are difficult to store with conventional shelving, our cantilever racking system offers superior functionality and flexibility.

Cantilever Racking is available in both single-sided and double-sided configurations, each tailored to maximize storage efficiency. The double-sided cantilever rack provides exceptional storage capacity with a single central column, making it ideal for high-density storage environments. On the other hand, the single-sided rack is perfect for locations where space is limited, allowing the rack to fit flush against a wall.

The Hyperack Cantilever Racking System combines efficiency, versatility, and cost-effectiveness, making it an essential choice for any warehouse or storage facility. Enhance your storage capabilities with our cantilever racks and experience the benefits of optimized space utilization and improved accessibility.

Ideal for

- Oversized Products – Ideal for items that cannot be safely blocked or stacked

- Fast-Moving Consumer Goods (FMCG)

Advantages

- High-Density Storage – maximizes cubic space

- Versatile Storage Locations

- Flexible Cantilever Arms – ensuring a customized storage solution

5 Easy Steps

1. Enquiry

Your journey begins with a simple enquiry. Once we receive your request, our team will review the details and match you with the right expert. We’ll then arrange a quick call or email to learn more about your goals and expectations.

2. Free Consultation

After your initial consultation, we’ll arrange a site visit to assess your space and needs in detail. You’ll meet your dedicated project manager, who will guide the process from start to finish—ensuring everything runs smoothly and efficiently.

3. 3D CAD Design

After the site survey, your project manager will recommend layout options tailored to your space and needs. We’ll then create accurate 3D CAD designs to help you visualise exactly how your facility will look once complete.

4. Instant Quote

You’ll receive a free, personalised quote with a full breakdown of the recommended equipment. We offer high-quality products at competitive prices, with reliable delivery times to keep your project on schedule.

5. Installation

We’ll agree on an installation schedule that suits your operations. Our accredited team will complete the setup, conduct a final inspection with you, and provide follow-up support, including annual safety checks.

Ready to make a change?

We are here to help you choose the best racking for your business. Schedule a call with our representative today.

FAQ

What types of items are best suited for Cantilever Racking?

Cantilever Racking Systems are engineered for storing long, irregularly shaped, and heavy materials that cannot be efficiently stored on conventional shelving. These include items such as steel bars, pipes, timber beams, oversized furniture, and construction materials. The system’s robust horizontal arms are designed to handle the weight and length of these materials, ensuring stability and safety. With adjustable arm lengths and load-bearing capacities, cantilever racks accommodate products of varying sizes and weights, providing a highly versatile solution for industries like construction, manufacturing, and logistics.

How do cantilever Cantilever Racking improve warehouse efficiency?

Cantilever Racking Systems significantly improve warehouse space utilization and operational flow. By eliminating the need for vertical columns between each shelf, the system offers an uninterrupted horizontal storage space, ideal for long items. This design allows for the storage of products with greater flexibility, as the arms can be adjusted to different heights. Additionally, the open-front design allows for easy access, reducing handling time and enabling faster picking, loading, and unloading. The system also supports high-density storage, making it ideal for warehouses with large inventories of bulkier items, enhancing throughput and overall storage efficiency.

What are the key differences between single-sided and double-sided Cantilever Racking?

- Single-sided Cantilever Racks: These are designed for placement along walls or partitions and are accessed from one side. They typically have a lower initial setup cost and are perfect for applications where only one side needs to be accessible. They are ideal for smaller spaces or operations where limited storage volume is required.

- Double-sided Cantilever Racks: These systems provide access to both sides, doubling the available storage space. With a central upright and arms extending in both directions, double-sided racks are optimized for high-density storage areas and applications requiring fast access to both sides of the rack. They maximize storage capacity in large warehouses by efficiently utilizing the available floor space, especially in high-traffic environments.

How can I customize a Cantilever Racking System to suit my storage needs?

Cantilever Racking Systems offer extensive customization options to meet the specific needs of different industries and types of products. Key customization features include:

- Arm length and spacing: The arms can be adjusted to varying lengths (typically between 24” and 72”) and spaced based on the dimensions of the materials to be stored.

- Weight capacity: Depending on the product being stored, cantilever arms can be designed to support different weight capacities, typically ranging from 500 kg to 4,000 kg per arm.

- Frame height: Racking frames can be customized to various heights, typically from 3 meters to over 9 meters, allowing for efficient vertical space utilization.

- Material and coating: Arms and frames can be made from heavy-duty steel, and coatings like powder coating or galvanization can be applied to ensure rust resistance in specific environments (e.g., outdoor storage).

What are the maintenance requirements for Cantilever Racking Systems?

To ensure the continued safety and functionality of Cantilever Racking Systems, regular technical maintenance is necessary:

- Structural inspections: Routine checks should be performed on the uprights, arms, and base plates for signs of stress, wear, or damage. Any bends, cracks, or misalignments should be addressed immediately.

- Arm load testing: Overloading can compromise the structural integrity of the arms. Ensuring that the racks are not loaded beyond their designed weight capacity is essential to avoid rack failure.

- Base stability checks: For stability, verify that the base is level and firmly anchored to the ground, particularly for high-load systems or double-sided racks. This ensures the racks can handle the intended loads without tipping.

- Periodic coating checks: In humid or corrosive environments, inspect the coating on the arms and frames to prevent rust. Re-coating may be necessary for long-term durability, especially for outdoor use or in cold storage areas.

What are the advantages of using Cantilever Racking over traditional shelving systems?

So, if you’ve got bulky or oddly shaped items like pipes, timber, or furniture to store, cantilever racking is a game-changer. Unlike your regular shelving, the arms are open and don’t have those vertical posts in the way, giving you more space and making it easier to grab what you need. It’s all about making the most of your space while keeping everything accessible.

How do I determine the appropriate load capacity for my Cantilever Racking System?

Figuring out the right load capacity depends on a few things like the material strength, how long the arms are, and what you’re storing. The best way to go is to chat with your racking supplier, who can help match your needs with the right system based on how heavy and big your stuff is. You don’t want to overload the racks, so getting the right specs is key.

Are Cantilever Racking Systems suitable for outdoor storage applications?

Absolutely! Cantilever racking can work outdoors too, but if you’re going this route, make sure the racking is made with materials that can stand up to the weather—think galvanized steel to avoid rust. Just make sure the system is properly anchored, especially in areas that can get windy, so everything stays safe and secure.

What safety considerations should be taken into account when installing and using Cantilever Racking?

Safety is a big deal, so get it right from the start. Always follow the installation guidelines from the manufacturer or work with pros to set it up. After that, it’s about regular check-ups—inspect the racks for wear and tear. And, make sure the load isn’t too heavy for the system, and that it’s evenly distributed. This prevents any potential mishaps or damage.

How can I optimize the layout of my warehouse using Cantilever Racking to maximize storage space?

When it comes to optimizing, think about the layout in a way that gives you easy access to what you need. Place your cantilever racks along the aisles for easy reach. You can mix up single-sided and double-sided racks depending on how your warehouse is set up. Plus, having adjustable arms lets you tweak things as your storage needs change, so you’re always making the best use of your space.