Warehouse racking

Boltless Rack

A boltless rack is a type of shelving system that doesn’t require nuts or bolts for assembly. Instead, it uses a system of interlocking parts, such as clips, notches, or rivets, to secure the components together. This innovative design makes the boltless rack an ideal solution for quick and easy setup without compromising on stability and durability.

Hyperack Boltless Rack is manufactured by our skilled team to meet the highest standards of quality and reliability. Commonly used in stores, businesses, homes, and various other settings, the boltless rack is perfect for displaying, storing, or offering items for sale. Its versatility and ease of assembly make it a popular choice for those looking to optimize their storage space.

One of the standout features of the Hyperack Boltless Rack is its ability to be raised off the ground and usually anchored or supported on its shorter length sides by brackets. This design not only maximizes floor space but also provides a secure and organized way to keep items within reach. In retail environments, the front edge of the shelf under the objects can be used to display important information such as the name, product number, pricing, and other details about the items.

Choosing a boltless rack system like the one offered by Hyperack ensures that you get a flexible, durable, and efficient storage solution. Whether you need to organize your garage, warehouse, or retail space, our boltless racks provide the support and accessibility you need.

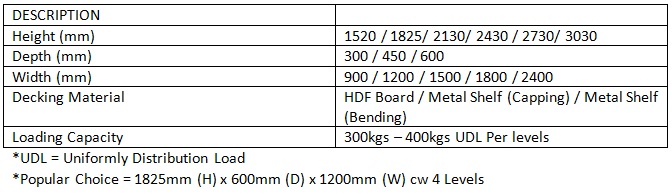

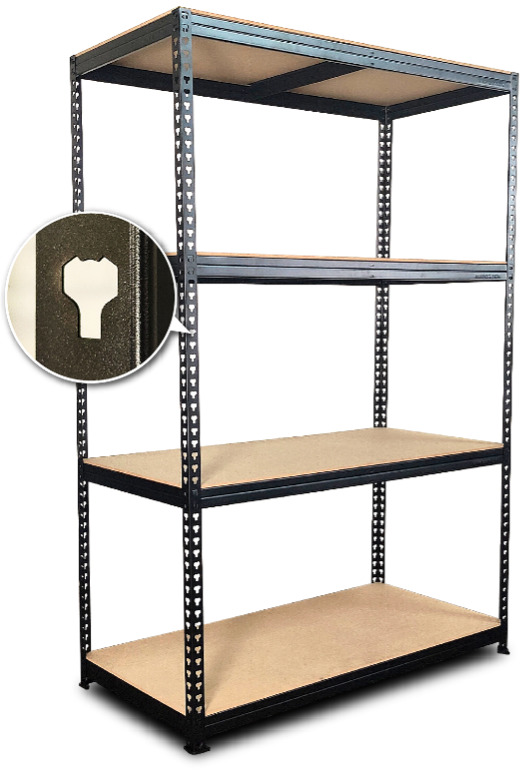

Boltless Rack is one of the signature product in HYPERACK. Industrial-grade shelving at budget prices. Suitable for storing larger, bulkier items in the factory, warehouse, stockroom and Garage. Manufactured from premium-grade Malaysia steel and available with fully-adjustable levels.

- Shelves adjustable every 35mm

- Finished in powder-coated blue and high visibility yellow

- High-density fibre board shelves with steel central supports

- Tested and certified to SIRIM manufacturing and safety standards

- Simple boltless assembly – just tap sections together with a rubber assembly mallet

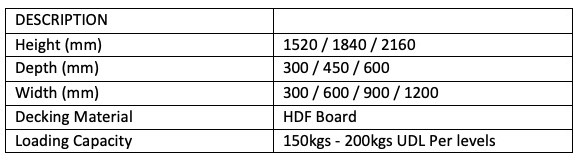

LIVIN BOLTLESS RACK

Low-profile boltless rack. This light-industrial version of our Livin series is a popular choice in stockrooms, storerooms and garages for more than 25 years. General purpose shelving suitable for both commercial and domestic storage applications.

- Finished in powder-coated beige

- Boltless stud-and-keyhole design

- Supplied with protective foot protector

- Load capacity per shelf: 150kg – 200kg UDL*

- Simple and quick to build – just tap together with a rubber assembly mallet

5 Easy Steps

1. Enquiry

Your journey begins with a simple enquiry. Once we receive your request, our team will review the details and match you with the right expert. We’ll then arrange a quick call or email to learn more about your goals and expectations.

2. Free Consultation

After your initial consultation, we’ll arrange a site visit to assess your space and needs in detail. You’ll meet your dedicated project manager, who will guide the process from start to finish—ensuring everything runs smoothly and efficiently.

3. 3D CAD Design

After the site survey, your project manager will recommend layout options tailored to your space and needs. We’ll then create accurate 3D CAD designs to help you visualise exactly how your facility will look once complete.

4. Instant Quote

You’ll receive a free, personalised quote with a full breakdown of the recommended equipment. We offer high-quality products at competitive prices, with reliable delivery times to keep your project on schedule.

5. Installation

We’ll agree on an installation schedule that suits your operations. Our accredited team will complete the setup, conduct a final inspection with you, and provide follow-up support, including annual safety checks.

Ready to make a change?

We are here to help you choose the best racking for your business. Schedule a call with our representative today.

FAQ

What are the primary advantages of using Boltless Racks in industrial and commercial settings?

Boltless racks are highly favored in industrial and commercial environments due to their tool-free assembly and modular design. The interlocking components, typically rivets or clips, provide exceptional stability while allowing for easy reconfiguration of shelf heights without additional tools. This feature is particularly useful in warehouses and storage facilities where quick adjustments are necessary to accommodate different types of inventory. Moreover, the racks are designed with weight distribution in mind, ensuring they can handle heavy loads when properly assembled.

Can Boltless Racks be used outdoors, and how do environmental factors affect their performance?

While most boltless racks are designed for indoor use, certain models are engineered to withstand outdoor conditions, especially those made from galvanized steel or powder-coated materials. These materials offer additional protection against corrosion and rust, making the racks suitable for mild outdoor environments. However, exposure to extreme weather conditions (e.g., heavy rain or saltwater) can still degrade the integrity of the rack, particularly if it is not made from weather-resistant materials. For outdoor applications, ensure the racks are properly sheltered or choose racks with specific coatings to resist rust and other environmental damage.

How can I ensure the durability and longevity of my Boltless Racks in a high-traffic warehouse?

To extend the lifespan of boltless racks in high-traffic environments, it’s crucial to regularly inspect the structural integrity of the shelves and the interlocking components. Ensure that the rivets or clips are securely in place and that the weight distribution on each shelf is even, preventing overloading. If your warehouse stores heavy or bulky items, consider upgrading to heavy-duty boltless racks with reinforced steel beams or additional bracing. Periodic cleaning to remove dust and debris from the components will also help maintain the rack’s functionality and prevent damage from abrasive particles.

How much weight can a Boltless Rack handle, and how do I determine the right load capacity for my needs?

The load-bearing capacity of a boltless rack depends on the material, design, and dimensions of the rack. Standard boltless racks can typically support between 225 to 680 kilograms per shelf, while heavy-duty models may support up to 1,360 kilograms or more per shelf. When determining the appropriate load capacity for your rack, calculate the weight of the items you plan to store and ensure that the total weight is evenly distributed across all shelves. It’s also important to account for dynamic loading, where items are frequently added or removed, as this may affect the stability of the rack.

What materials are commonly used in the construction of Boltless Racks, and how do they impact performance?

Boltless racks are typically made from steel, aluminum, or high-density plastic, with steel being the most common due to its durability and strength. Steel racks may be galvanized or powder-coated for additional rust resistance. Aluminum racks, while lighter and more corrosion-resistant, tend to have a lower weight capacity compared to steel racks. The choice of material affects not only the rack’s load-bearing capacity but also its resistance to wear and tear, environmental factors, and the ease of handling and installation. For specialized applications, some racks may also use reinforced steel beams or wire mesh shelving to further enhance strength and airflow for specific storage requirements, such as for perishable goods or electronics.

How do I assemble a Boltless Rack, and do I need any special tools?

No special tools needed! Boltless racks are super easy to put together – no bolts or screws involved. All you need to do is slide the parts together, and they click into place. It’s really that simple and perfect if you’re looking for something quick and hassle-free.

Can I adjust the height or layout of my Boltless Rack?

Yep, most boltless racks are adjustable! You can change the shelf height or even rearrange the layout to fit whatever you need to store. It’s super flexible, so whether you’re changing up the storage or just need more room, it’s got you covered.

How much maintenance do Boltless Racks need?

Not much, really! Just check every now and then to make sure everything is securely in place and that nothing’s damaged. A quick cleaning every so often to keep things free from dust or debris will help them last longer and keep things running smoothly.

Can I use Boltless Racks in cold storage or fridges?

Absolutely! You can use them in cold storage, as long as they’re made from materials that can handle the low temps and won’t rust. Just check the manufacturer’s guidelines to make sure they’re good for your specific environment, and you’ll be all set.

How do I figure out what size or setup I need for my Boltless Rack?

Start by thinking about what you need to store – how heavy or big are the items? Then measure your available space to make sure the rack fits. If you’re unsure, you can always reach out to an expert or check the manufacturer’s recommendations to get the right fit for your needs.