Advanced Warehouse Racking Innovations: Maximizing Space & Efficiency

- 28/03/2025

- Posted by: macgad-admin

- Category: Racking System

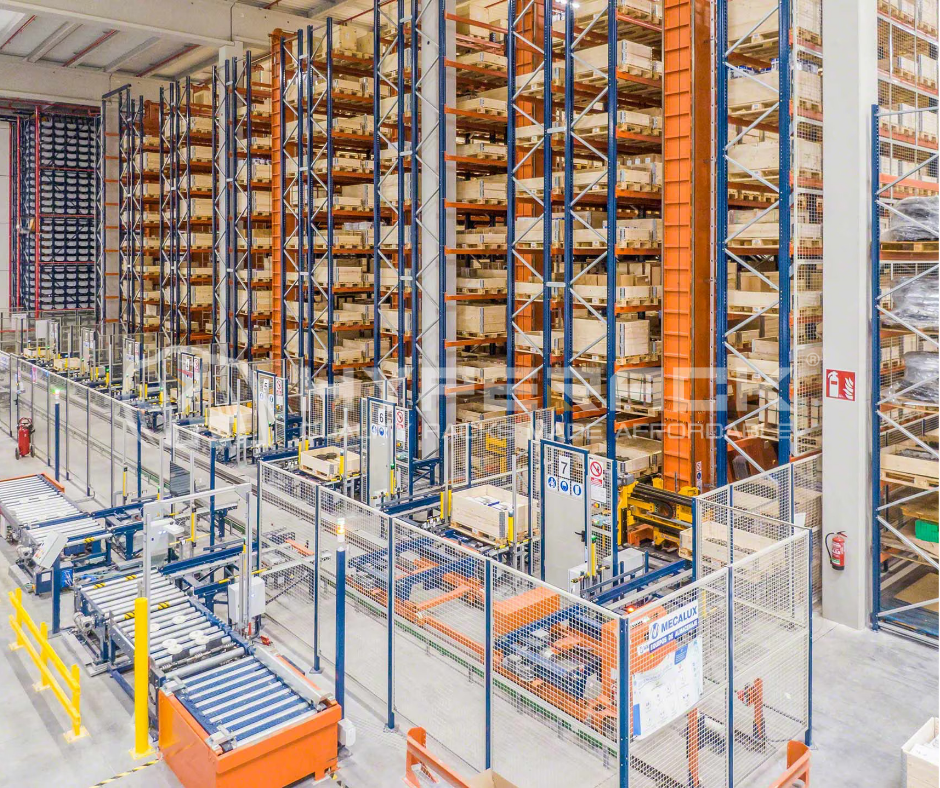

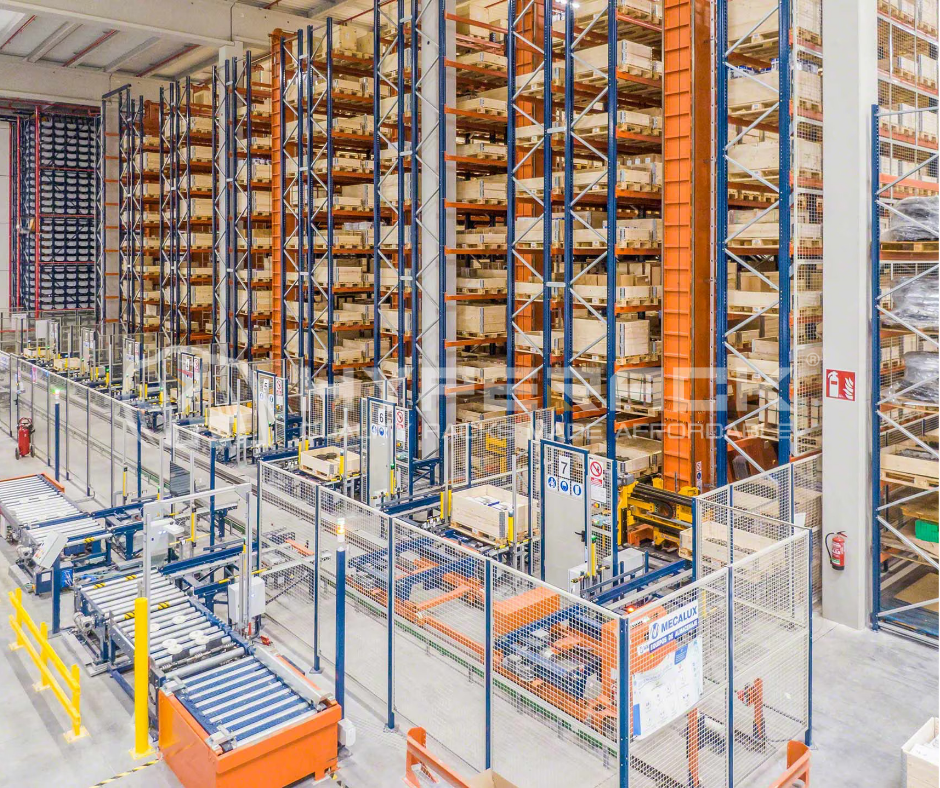

In the competitive world of warehousing and logistics, maximizing space while maintaining efficiency is paramount. Advanced warehouse racking innovations are transforming traditional storage solutions by incorporating cutting-edge technology and modular design, enabling businesses to optimize their space and streamline operations.

Introduction

Warehouse operations face constant pressure to increase capacity, improve safety, and reduce operational costs. Modern racking innovations are providing solutions that go beyond mere storageâdelivering enhanced functionality, flexibility, and technological integration. This article explores the latest trends and innovations in warehouse racking systems that are setting new benchmarks for efficiency and space management.

Evolution of Warehouse Racking Systems

Traditional vs. Advanced Racking

Traditional racking systems were designed with basic functionality in mind, often relying on fixed, rigid designs that offered limited adaptability. In contrast, advanced warehouse racking innovations incorporate:

- Modular Designs: Systems that can be reconfigured as inventory and operational needs evolve.

- Adjustable Components: Racks that adjust to different load sizes and weights, ensuring optimal space utilization.

- Enhanced Durability: Use of high-strength materials engineered for longevity and heavy-duty use.

Key Innovations Driving Efficiency

1. Modular and Flexible Designs

One of the most significant advancements is the adoption of modular racking systems. These designs allow for:

- Customizable Configurations: Easily adapting to changing inventory sizes and layouts.

- Scalability: Facilitating expansion without a complete overhaul of the existing system.

- Quick Reconfiguration: Minimizing downtime during upgrades or layout changes.

2. Integration of Smart Technologies

Advanced racking systems now often feature smart technologies that enhance both functionality and safety:

- IoT Sensors: Monitor load distribution, detect wear and tear, and provide real-time data for predictive maintenance.

- Digital Management Systems: Allow warehouse managers to optimize storage through data analytics and automated inventory tracking.

- AI-Driven Insights: Use machine learning algorithms to predict storage needs and optimize space allocation.

3. Improved Safety and Compliance

Enhanced safety is a core benefit of modern racking innovations:

- Real-Time Monitoring: Integrated sensors ensure that weight limits are respected and structural integrity is maintained.

- Compliance Ready: Designs that adhere to the latest safety standards and regulations, reducing liability and risk.

- Automated Alerts: Immediate notifications of potential issues, allowing for proactive maintenance and accident prevention.

Benefits of Advanced Warehouse Racking Innovations

Maximized Storage Capacity

By optimizing space through modular designs and smart configurations, warehouses can:

- Increase storage density without expanding physical footprint.

- Adapt to fluctuating inventory levels with flexible layouts.

- Enhance the overall efficiency of space utilization.

Enhanced Operational Efficiency

Advanced systems reduce labor and downtime through:

- Faster installation and reconfiguration.

- Automated inventory tracking and management.

- Reduced maintenance costs through predictive analytics.

Future-Proofing Warehouse Operations

Investing in advanced racking systems ensures that warehouses remain competitive by:

- Providing scalability for future growth.

- Integrating with emerging technologies like AI and IoT.

- Offering a sustainable solution that reduces waste and energy consumption.

Real-World Applications

Many industry leaders have already implemented these advanced systems with significant benefits:

- Case Study: A leading logistics company reconfigured its warehouse using modular racking systems, increasing storage capacity by 30% while reducing reconfiguration downtime by 40%.

- Industry Impact: Enhanced digital tracking and IoT integration have led to fewer maintenance issues and improved safety records across various warehouses.

Future Trends in Warehouse Racking

The future of warehouse storage lies in continued innovation:

- Smart Automation: Increased use of robotics and automated guided vehicles (AGVs) to interact seamlessly with smart racking systems.

- Data-Driven Decision Making: Leveraging big data to continuously optimize storage layouts and operational workflows.

- Sustainable Practices: Integrating eco-friendly materials and energy-efficient designs to reduce environmental impact while improving performance.

Conclusion

Advanced warehouse racking innovations are reshaping how businesses manage space and efficiency. By embracing modular designs, smart technologies, and enhanced safety features, warehouses can achieve unprecedented levels of productivity and adaptability. Investing in these innovations not only optimizes current operations but also paves the way for future growth and sustainability.