What is ASRS Racking?

In today’s fast-paced business landscape, Automated Storage and Retrieval Systems (ASRS) are transforming how Malaysian companies manage their warehouses. Given the rising demand for efficiency, ASRS provides an innovative solution that automates the storage and retrieval of goods. As a result, it optimizes space and reduces labor costs. In fact, research shows that businesses can increase their storage capacity by up to 50% with ASRS, making it a smart choice for warehouses looking to enhance operations. Thus, in this article, we’ll explore the ins and outs of ASRS racking systems, how they function, and why they could be a game-changer for your warehouse efficiency.

How Does an ASRS Racking System Work?

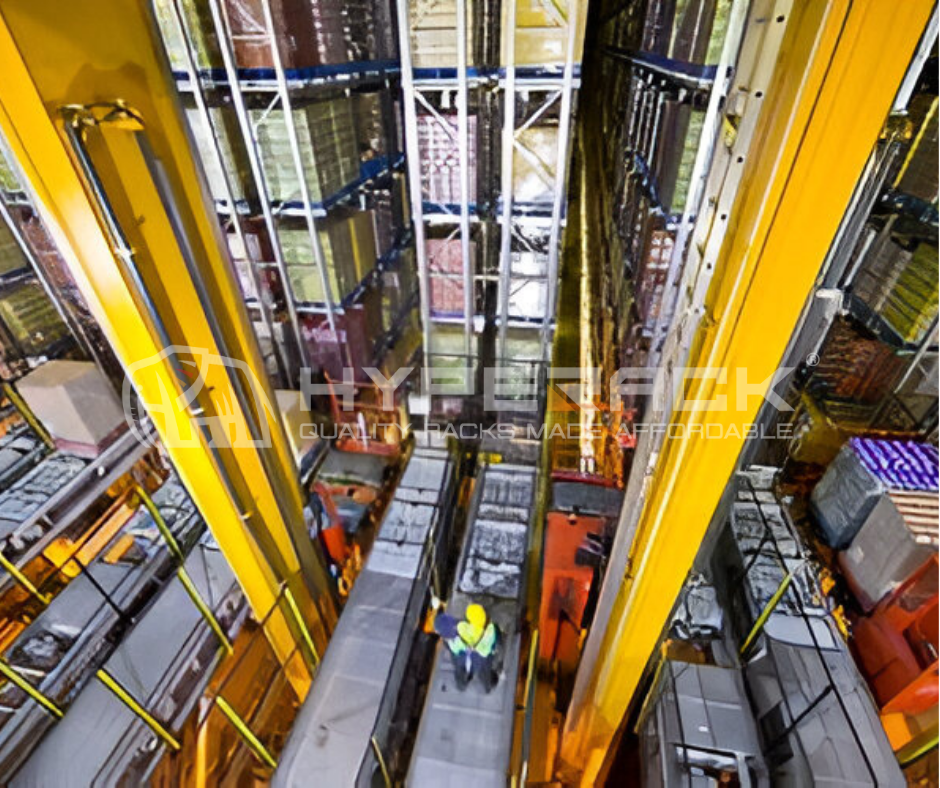

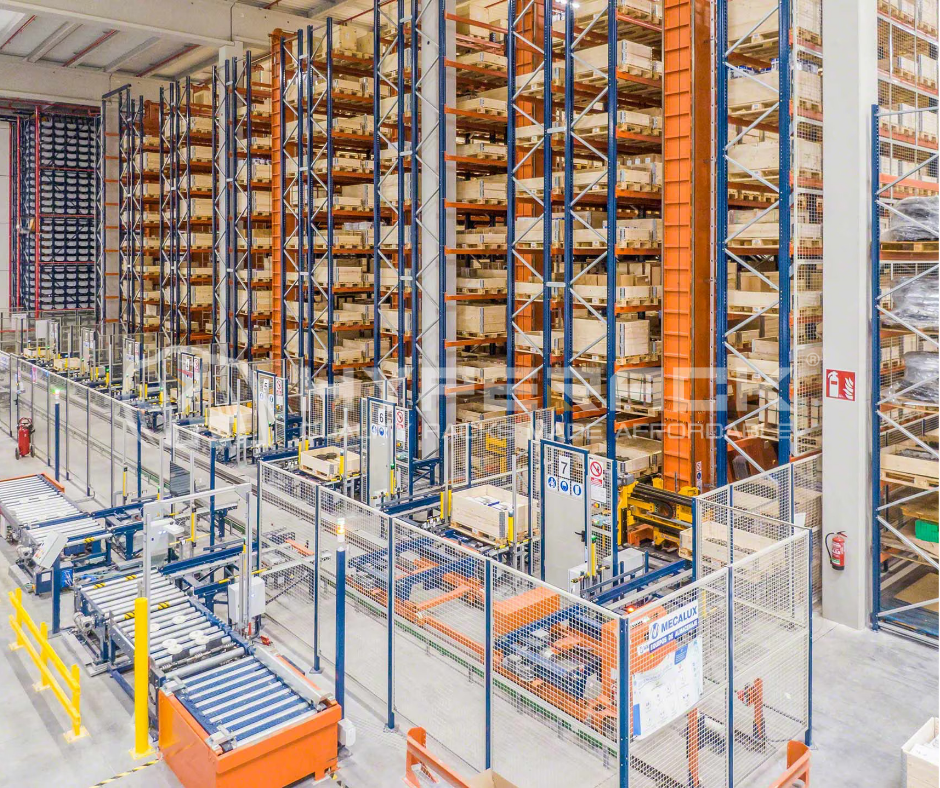

You might wonder, how does ASRS actually work? At its core, an ASRS racking system employs advanced automated machinery to streamline the process of storing and retrieving pallets or items. To elaborate, this high-tech solution includes components such as shuttles, conveyors, and stacker cranes that work together to efficiently manage inventory.

For instance, when you need to store a product, it is placed on a conveyor belt that leads into the ASRS system. Then, automated shuttles transport the pallet to its designated spot in the racking system. Moreover, when it’s time to retrieve an item, the system quickly locates the pallet and sends it back via the conveyor. As a result, this seamless automation not only maximizes vertical space but can also cut labor costs by up to 30%, allowing your team to focus on more critical tasks.

Benefits of an ASRS Racking System

ASRS racking systems come with a host of benefits tailored specifically for Malaysian businesses:

- Maximized Storage Density

First and foremost, ASRS systems utilize vertical space to provide up to 50% more storage capacity compared to traditional racking solutions. This is particularly important for warehouses dealing with space constraints. - Cost Efficiency

Furthermore, with reduced manual handling and faster retrieval times, ASRS systems help lower labor costs. Typically, installation expenses range from a minimum is RM600 per pallet position, making it a worthwhile investment for high-volume operations. - Enhanced Inventory Management

In addition, maintaining accurate inventory levels is crucial for success. ASRS systems offer real-time tracking, thereby reducing the risk of stockouts and improving order-picking speeds. As a result, many businesses report increased accuracy and faster fulfillment times, which can significantly boost customer satisfaction. - Flexibility and Scalability

Moreover, ASRS systems adapt easily to various warehouse sizes and can grow with your business, making them suitable for diverse industries—from e-commerce to manufacturing.

When to Use ASRS Racking Systems?

You might be asking yourself, when should I consider ASRS for my warehouse? Here are some key scenarios:

- High Turnover Rates: If your business handles a lot of fast-moving items, ASRS can significantly improve picking speed and reduce retrieval times.

- Space Constraints: For warehouses located in densely populated areas, ASRS maximizes storage without requiring additional floor space.

- Need for Inventory Accuracy: If precise inventory management is a priority, ASRS provides advanced tracking capabilities that minimize human error.

ASRS Racking System vs. Other Racking Systems

Choosing the right storage system is vital. Here’s how ASRS compares with other popular racking options:

| Feature | ASRS Racking | Selective Racking | Drive-In Racking | Push Back Racking |

|---|---|---|---|---|

| Storage Density | Very High | Medium | Very High | High |

| Accessibility | Low | High | Low | Moderate |

| Equipment Needed | Specialized Automation | Standard Forklifts | Specialized Forklifts | Specialized Forklifts |

| Best For | High-volume, fast-moving items | Variety of SKUs | Bulk storage | FIFO inventory |

For example, while Selective Racking allows quick access to every pallet, it has lower storage density. In contrast, Drive-In Racking maximizes density but limits access to the last-loaded pallets, making ASRS a more efficient choice for many high-turnover operations.

Installation Guide for an ASRS Racking System in 2024

Setting up an ASRS racking system involves careful planning. Here’s a straightforward guide to help you get started:

- Assess Your Needs: Evaluate your warehouse operations and determine the best layout for the ASRS system to optimize workflow.

- Calculate Load Capacity: Ensure that your ASRS can handle the weight and dimensions of your inventory, typically supporting loads from 500 to 2,500 kilograms per pallet position.

- Design the System: Collaborate with a reputable supplier to create a system that meets your specific requirements, including the type of automation best suited for your operation.

- Install and Test: After installation, conduct thorough testing to ensure everything runs smoothly and efficiently.

Cost of Installing an ASRS Racking System

The installation cost of an ASRS racking system can vary widely based on specifications, automation features, and materials. For instance, basic systems may start at around RM600 per pallet position. Therefore, to get a more accurate estimate, it’s essential to consult different providers. Many suppliers, like Hyperack, offer free consultations to help you identify the best solution for your warehouse needs.

Best Racking System Provider?

Selecting the right ASRS provider is crucial for a successful implementation. Here are some tips to find a reputable supplier:

- Research Local Suppliers: Look for companies in Malaysia with a solid track record in ASRS installations. Additionally, customer testimonials can provide insights into their reliability and service quality.

- Verify Certifications: Ensure the provider complies with industry standards and safety regulations, which is crucial for product quality.

- Evaluate Customer Support: Choose a provider that offers comprehensive customer service, including installation, training, and ongoing support.

- Compare Pricing and Warranties: Obtain quotes from multiple suppliers to find the best deal. Moreover, review warranty terms to safeguard your investment.

Ready to enhance your warehouse efficiency? At HYPERACK, we specialize in double deep racking systems tailored to meet your specific needs. Contact us today for a FREE consultation, and let our experts help you optimize your storage solution! Explore our social media to see real-life projects in action.

Conclusion

In conclusion, ASRS racking systems present a cutting-edge, efficient, and cost-effective solution for warehouses in Malaysia. They are particularly beneficial for operations that demand high-density storage while ensuring quick access to inventory. By maximizing space and enhancing productivity, ASRS can be a valuable asset for businesses striving to succeed in Malaysia’s competitive market.

How Hyperack Plan Your Racking System?

- Expertise: We dive deep into your warehouse space to determine the best racking configurations tailored to your needs.

- High-Tech Solutions: Our AutoCAD designs maximize storage while ensuring your team has ergonomic access to what they need.

- Side-by-Side Comparisons: Our planning process allows you to compare layout options easily, helping you make informed decisions.

- Data-Driven ROI Calculation: We provide detailed numerical data for each layout, empowering you to understand the impact on your bottom line.

- Customization: Our custom racking systems are built to meet any unique requirements, ensuring the best approach for any facility.